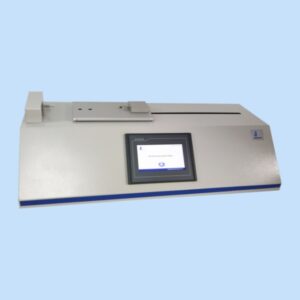

SPPT-01 Syringe Positive Pressure Tightness Tester

- Standard: ISO 7886-1

- Tillverkare: Cellinstrument

- Ansökningar: Förpackningsmaterial, material för medicintekniska produkter, farmaceutiska tester och mer.

- Anpassning: Tillgänglig för speciella testkrav och automationstransformationer

Ensuring the integrity of disposable syringes is critical for patient safety and product quality in pharmaceutical and medical device manufacturing. Among the most important assessments is the syringe liquid leak test, particularly at the plunger stopper under compression. This test verifies whether any leakage occurs when the plunger is subjected to both axial and radial forces under controlled conditions. Cell Instruments offers an advanced solution to perform this test with precision and repeatability—the SPPT-01 Syringe Positive Pressure Tightness Tester.

Syringe Liquid Leak Tester - ISO 7886-1

For laboratories and manufacturers seeking compliance with ISO 7886-1 Annex D, the SPPT-01 Syringe Positive Pressure Tightness Tester by Cellinstrument provides a fully automated and precise testing solution. Designed with a PLC-controlled system och 7-inch touchscreen interface, the SPPT-01 offers:

- Adjustable test speeds (1–500 mm/min)

- High-accuracy measurement (0.01 mm)

- Interchangeable fixtures for various syringe sizes

- Sideways and downward force application in one integrated platform

- Överbelastningsskydd och automatic return for enhanced safety

- On-board mikroskrivare for immediate test reporting

These features ensure consistency, accuracy, and adherence to global regulatory standards like ISO 7886-1.

Huvudparameter

| Lastcell | 200N (eller efter behov) |

| Testa hastighet | 1~500 mm/min |

| Noggrannhet | 0,01 mm |

| Driva | 110~220V |

Applications and Industry Relevance

The syringe liquid leak test applies to manufacturers of:

- Hypodermic syringes

- Pre-filled syringes

- Medical injection systems

- Quality inspection and regulatory testing labs

By incorporating this test into quality control protocols, companies in pharmaceutical, medical device, och packaging sectors can meet international regulatory requirements and strengthen product reliability.

Importance of Syringe Liquid Leak Test

The syringe liquid leak test is essential for quality assurance in the production of sterile hypodermic syringes. A leaking syringe poses significant risks, including contamination, inaccurate dosing, and failure during administration. By conducting a controlled syringe liquid leak test, manufacturers can identify weaknesses in the syringe’s plunger stopper design and prevent defective units from reaching the market.

Test Method Based on ISO 7886-1 Annex D

ISO 7886-1 is the international standard for sterile hypodermic syringes for single use. The ISO 7886-1 testing procedure ensures the mechanical and functional performance of the syringe, including leakage resistance. Specifically, ISO 7886-1 Annex D outlines the test method for liquid leakage at the syringe plunger stopper under compression.

ISO 7886-1 is the international standard for sterile hypodermic syringes for single use. The ISO 7886-1 testing procedure ensures the mechanical and functional performance of the syringe, including leakage resistance. Specifically, ISO 7886-1 Annex D outlines the test method for liquid leakage at the syringe plunger stopper under compression.

Test Principles from ISO 7886-1 Annex D

The Annex D procedure aims to simulate worst-case conditions by combining axial and radial loads on the syringe plunger:

- The syringe is first filled with distilled water above its nominal capacity.

- After expelling air, the volume is adjusted to the nominal level.

- The nozzle is sealed using a reference conical fitting in accordance with ISO 80369-7 or an equivalent seal.

- A sideways force (0.25 N to 3 N) is applied to the plunger to induce deflection.

- Axial pressure is generated in the range of 200–300 kPa and maintained for 30–35 seconds.

- Any leakage past the plunger stopper is examined visually.

This methodology ensures that the plunger stopper maintains a tight seal under pressure and lateral stress, replicating real-world conditions that could cause failure.

Equipment Requirements for ISO 7886-1 Annex D Testing

To perform the syringe liquid leak test accurately, the following equipment is required:

- A sealing device for the syringe nozzle.

- A fixture for applying radial force to the plunger.

- A pressurization device to reach 200–300 kPa.

- Distilled water (18°C to 28°C) for the filling process.

Vanliga frågor

The syringe liquid leak test evaluates whether the plunger stopper maintains a proper seal under compression, preventing any leakage that could compromise sterility or dosage accuracy.

The SPPT-01 tester applies both radial and axial forces to the syringe plunger while the nozzle is sealed, simulating worst-case conditions to identify any leakage past the stopper.

It ensures that every syringe delivers medication safely and accurately, preventing contamination, dosage loss, or injection failures.

Yes, the SPPT-01 comes with multiple fixtures to accommodate a wide range of syringe types and capacities, enhancing its versatility for different testing needs.

Ensuring a syringe’s ability to maintain a leak-free seal under pressure is essential for safety and performance. The syringe liquid leak test, as defined in ISO 7886-1 Annex D, provides a standardized and reliable method to evaluate this critical property. Using a precise and fully compliant instrument like the SPPT-01 Syringe Positive Pressure Tightness Tester från Cellinstrument helps manufacturers maintain quality standards and protect end users.