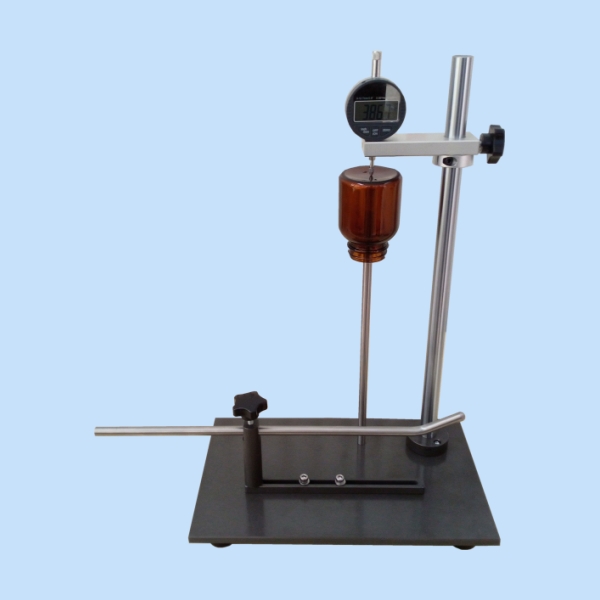

WTT Wall Thickness Tester

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

I. Introduction of Glass Bottle Wall Thickness Tester

1. Purpose and Importance in Various Industries

The Glass Bottle Wall Thickness Tester is a critical instrument in various industries, ensuring the quality and safety of glass containers. In the packaging industry, particularly for beverages, pharmaceuticals, and cosmetics, precise wall thickness measurements are essential for maintaining structural integrity and compliance with safety standards. The glass bottle wall thickness tester helps in identifying any inconsistencies or weaknesses in the glass bottles, preventing potential failures during filling, transportation, and storage.

2. Key Features and Benefits

The WTT series is specifically designed for measuring the wall thickness of packaging containers with complex patterns, offering user-friendliness, durability, and high precision. Some key features include:

- Electronic Digital Display: Provides accurate measurement results with easy-to-read data.

- Versatile Measurement Capability: Capable of measuring both the bottom and wall thickness, making it suitable for various container types.

- Data Transfer Option: An optional data cable is available for transferring data to MS Excel format on a PC, facilitating data analysis and record-keeping.

II. Main Parameters

The main parameters of the Glass Bottle Wall Thickness Tester are as follows:

| Sample Diameter | 5-50mm/10-120mm(Customization available) |

| Test Range | 0-12.7mm |

| Division value | 0.01mm/0.001mm(optional) |

| Measurable Height | 100/300mm (Customization available) |

III. Working Principle

1. How the Glass Bottle Wall Thickness Tester Works

The Glass Bottle Wall Thickness Tester uses the contact method to measure thickness. This method involves physically touching the surface of the bottle with a specialized measuring tool to determine the thickness of its walls. It is a direct and accurate technique, ensuring precise measurements essential for quality control.

2. Process Flow from Sample Placement to Obtaining Results

- Sample Placement: The glass bottle is placed on the tester’s platform.

- Measurement Tool Contact: The measuring tool contacts the surface of the bottle.

- Data Recording: The thickness measurement is recorded and displayed digitally.

IV. Test Methods

Standard Testing Procedures

- Preparation of the Glass Bottle Samples:

- Clean the glass bottles to remove any dirt or residues.

- Ensure the bottles are dry before measurement.

- Calibration and Setup of the Instrument:

- Calibrate the tester according to the manufacturer’s instructions.

- Set the appropriate measurement range and division value.

- Performing the Measurement and Recording the Data:

- Place the bottle on the tester’s platform.

- Adjust the measuring tool to contact the bottle’s surface.

- Record the thickness readings displayed on the digital screen.

- Post-Test Analysis and Interpretation of Results:

- Transfer data to a PC if using the optional data cable.

- Analyze the results to identify any variations or defects.

- Interpret the data to ensure the bottles meet required standards.

V. Applications

Industries and Applications

The Glass Bottle Wall Thickness Tester is used in a variety of industries:

- Packaging Industry: Essential for ensuring the durability and safety of beverage, pharmaceutical, and cosmetic containers.

- Quality Inspection and Compliance: Helps in maintaining compliance with industry standards and regulations.

- Research and Development: Useful in the development of new glass container designs and materials.

VI. Advantages of Using Glass Bottle Wall Thickness Tester

Benefits Over Other Methods

- Accuracy and Precision: Provides highly accurate and precise measurements, ensuring the reliability of results.

- Non-Destructive Testing: The contact method is non-destructive, preserving the integrity of the sample.

- Speed and Efficiency: Offers quick measurements, enhancing productivity.

- User-Friendly Interface and Ease of Use: Simple operation with a clear digital display, suitable for various skill levels.

VII. FAQs

1. Can the tester measure bottles of different shapes and sizes?

Yes, the tester can measure bottles of various shapes and sizes within the specified sample diameter range of 5-50mm, with customization options available for different requirements.

2. What is the typical measurement range and accuracy?

The typical measurement range is 0-12.7mm, with a division value of 0.01mm or 0.001mm (optional), providing highly accurate results.

3. Are there any special requirements for operating the tester?

The tester requires calibration before use to ensure accuracy. It is also essential to handle the glass bottles carefully to avoid any damage during measurement.

4. How does the tester handle variations in glass thickness?

The tester provides precise measurements that can detect even small variations in glass thickness, ensuring that all parts of the bottle meet the required standards.

5. Is there an option to transfer measurement data to a computer?

Yes, an optional data cable is available to transfer measurement data to MS Excel format on a PC, facilitating data analysis and record-keeping.