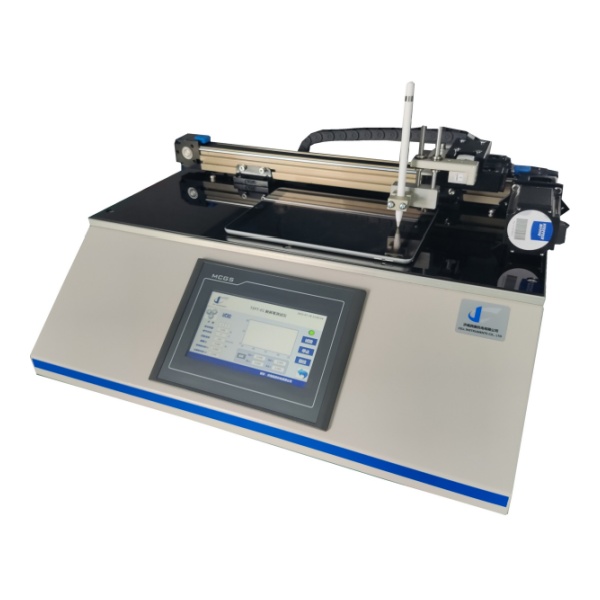

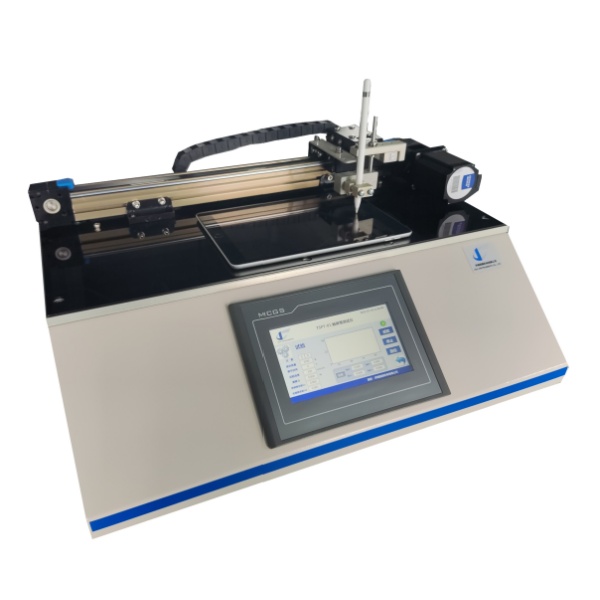

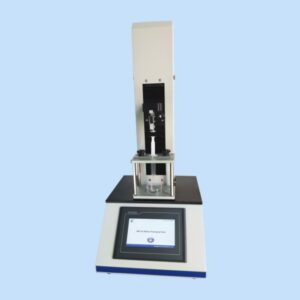

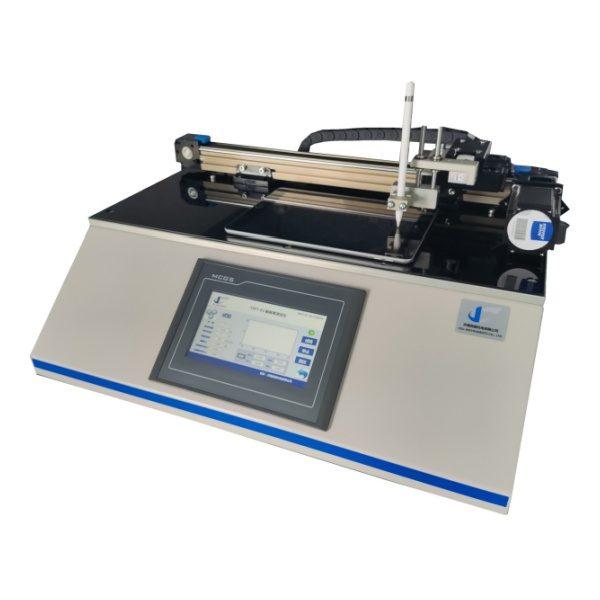

TSTP-01 Stylus Pen Sliding Coefficient of Friction Tester

- Standard: ASTM D1894, ISO 8295

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

The stylus pen sliding coefficient of friction tester is a highly specialized instrument designed to measure the frictional properties of stylus pens. This device plays a crucial role in ensuring the quality and performance of stylus pens used in various industries. The importance of measuring the coefficient of friction lies in its direct impact on the usability and durability of stylus pens, which are widely used in electronics, packaging, and quality inspection industries. Understanding the frictional characteristics helps manufacturers enhance the design and functionality of their stylus products, leading to improved user experience and product longevity.

I. Key Features and Benefits

The TSTP-01 Stylus Sliding and Coefficient of Friction Tester stands out as an advanced and indispensable tool for testing laboratories and stylus manufacturers. Here are its key features and benefits:

- PLC Controlled Operation: Ensures industrial-level stability and precision during testing.

- User-Friendly Interface: Operated through an HMI screen for easy and intuitive control.

- High-Speed Linear Movement Guide: Provides accurate and consistent sliding motion, critical for reliable test results.

- Specially Designed Stylus Holding Jig: Guarantees secure and precise positioning of the stylus during testing.

- Comprehensive Analysis: Evaluates both sliding behavior and the coefficient of friction, offering a complete assessment of stylus performance.

These features make the TSTP-01 an ideal tool for analyzing and improving the quality of stylus products, ensuring they meet the stringent demands of modern applications.

II. Technical Specifications

| Force Range | 5N |

| Accuracy | 0.5%FS |

| Speed Adjustable | 1~12000mm/min |

| Speed Accuracy | 0.1mm/min |

| Pressing Weight | 150g |

| Stroke | 350mm |

| Power Supply | 110~220V, 50/60Hz |

III. Test Methods

1. Principle of Operation

The stylus pen sliding coefficient of friction tester operates by measuring the resistance encountered by a stylus as it slides across a surface. This resistance, or friction, is quantified to determine the coefficient of friction. Consistent testing conditions are vital to obtain accurate and reproducible results. The instrument simulates real-world usage conditions, providing valuable data on how a stylus will perform in actual applications.

2. Preparation for Testing

- Sample Preparation: Ensure the stylus and the test surface are clean and free from contaminants.

- Calibration: Calibrate the instrument according to the manufacturer’s guidelines to ensure accuracy.

- Setup: Secure the stylus in the specially designed holding jig and position it over the test surface. Select the appropriate test mode and parameters on the HMI screen.

3. Conducting the Test

- Parameter Setting: Input the required speed, force, and distance settings.

- Initiating the Test: Start the test via the HMI screen, ensuring all parameters are correctly set.

- Monitoring: Observe the test progress and ensure the instrument operates smoothly throughout the process.

4. Data Collection and Analysis

The instrument collects data on friction force and sliding distance during the test. This data is then analyzed to determine the coefficient of friction and assess the wear resistance of the stylus tip. Accurate interpretation of the results helps in identifying potential improvements in stylus design and material selection.

IV. Customization

1. Testing Items

The TSTP-01 tester can be customized to evaluate various testing items such as stylus tip materials, different surface types, and varying environmental conditions.

2. Sample Fixture

Custom fixtures can be designed to accommodate different stylus shapes and sizes, ensuring secure and precise testing.

3. Others

Additional customization options include software enhancements for data analysis, extended test modes.

V. Standards

ASTM D1894 and ISO 8295 can be used as a reference.

VI. FAQ

The coefficient of friction measures the resistance encountered when one surface slides over another. For stylus pens, a lower coefficient indicates smoother interaction with touchscreens, enhancing user experience.

The instrument should be calibrated before each testing session or at regular intervals specified by the manufacturer to ensure accurate results.

Yes, the tester can be adapted to measure the coefficient of friction for various materials, not just stylus pens.

Basic training on the instrument’s operation and software interface is recommended. The user manual and manufacturer’s support can provide additional guidance.

The TSTP-01 Stylus Pen Sliding and Coefficient of Friction Tester is an essential tool for manufacturers and testing laboratories focused on improving stylus performance. Its advanced features and reliable operation ensure accurate measurement of frictional properties, helping to enhance product quality and durability. For more information or to request a demo, please contact us.