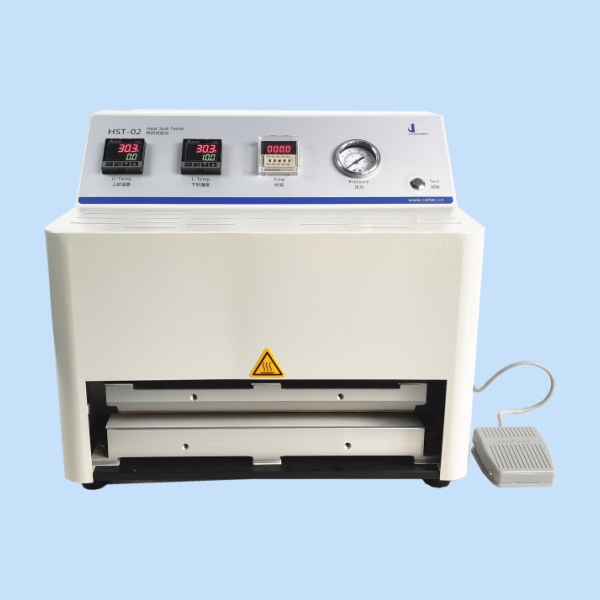

HST-02 Heat Seal Tester

- Standard: ASTM F2029

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

The Laboratory Heat Sealer plays a critical role in packaging material testing, ensuring that seals in flexible packaging materials meet industry standards for quality and durability. This instrument is indispensable in industries such as food packaging, pharmaceuticals, medical devices, and electronics. By controlling essential factors like temperature, pressure, and time, a laboratory heat sealer recreates the sealing process under controlled conditions. The performance of a heat seal directly affects the functionality, safety, and overall integrity of packaging.

I. Application of the Laboratory Heat Sealer

A Laboratory Heat Sealer is an essential tool used in various industries to assess the heat sealability of flexible barrier materials, including thermoplastics, films, laminates, and composites. Packaging materials in the food, pharmaceutical, and medical sectors require seals that not only secure the contents but also protect them from external factors like air, moisture, and contamination.

Laboratory heat sealers are designed to test and optimize heat sealing conditions for different materials. By adjusting three critical parameters—temperature, pressure, and time—these devices allow manufacturers to achieve optimal sealing results. An effective seal ensures both product safety and ease of use for consumers, as poorly sealed packages may lead to product spoilage or contamination.

II. Technical Features of the Laboratory Heat Sealer

The performance of a Laboratory Heat Sealer hinges on the precise control of temperature, pressure, and time. The following technical features are crucial for accurate and consistent testing:

- Temperature Control: A proportional integral derivative (P.I.D.) temperature controller ensures precise heat regulation. The aluminum construction of the upper and lower sealing jaws minimizes heat loss, maintaining uniformity across the sealing surface.

- Pressure Consistency: A guided sealing bar provides stable and consistent pressure throughout the sealing process, ensuring uniform seals.

- Time Accuracy: A precise timer, synchronized with a proximity sensor, ensures that the sealing time is consistent with jaw movement. This precision is essential for repeatable results in laboratory testing environments.

- User Safety Features: To ensure operator safety, heat sealers are equipped with features like anti-scald covers and allow for both manual and foot switch initiation to minimize direct contact with hot surfaces.

III. ASTM F2029: Standard for Heat Seal Testing

When conducting tests with a Laboratory Heat Sealer, it is essential to follow recognized standards to ensure that results are consistent and reliable. One of the most widely used standards is ASTM F2029. This standard outlines the practices for making laboratory heat seals for the determination of heat sealability of flexible barrier materials.

ASTM F2029 and Its Relevance

ASTM F2029 provides a structured approach to testing by specifying the critical factors that need to be controlled during the heat sealing process: temperature, time, and pressure. According to ASTM F2029-16(2021), this standard is used to measure the seal strength of flexible materials, ensuring that the heat sealing process delivers strong and reliable seals. The standard also offers guidelines on how to prepare test samples, set up the heat sealer, and evaluate the quality of the resulting seals.

Compliance with ASTM F2029 is crucial for manufacturers in regulated industries such as food and pharmaceuticals. It provides a benchmark for evaluating the seal integrity of packaging materials, which in turn helps manufacturers optimize their sealing processes and ensure their products meet regulatory requirements.

IV. The Laboratory Heat Sealer Testing Process

To perform a heat seal test using a Laboratory Heat Sealer, a sample of the packaging material is placed between two parallel sealing jaws. The following steps detail the typical testing process:

- Sample Placement: Place the material sample between the heated sealing jaws, ensuring even alignment.

- Setting the Parameters: Set the desired sealing temperature, pressure, and time according to the material type and testing standards. The laboratory heat sealer will allow for fine-tuning of these parameters.

- Sealing Process: Once the jaws reach the preset temperature, the upper jaw is pushed down onto the sample by a gas-driven cylinder, applying pressure for the set time duration.

- Completion of the Seal: After the specified time, the upper jaw returns to its original position, completing the seal. The entire process is carefully controlled to ensure that the same parameters are applied to every sample, allowing for repeatable and reliable results.

V. Significance of Heat Seal Testing

Heat seal testing is a vital quality control measure, especially in industries where the integrity of the packaging is crucial. The Laboratory Heat Sealer allows manufacturers to fine-tune their heat sealing processes, ensuring that seals are strong enough to withstand handling, shipping, and storage, but not so strong that they are difficult for consumers to open.

By controlling and testing seal strength, manufacturers can prevent issues like leaks, contamination, and product spoilage. Heat seal testing also helps identify the ideal conditions for sealing specific materials, which can improve packaging efficiency and reduce material waste.

VI. Seal Evaluation Methods

After the heat sealing process, the seal’s quality is evaluated through various methods, depending on the application and material. Common evaluation techniques include:

- Visual Inspection: A straightforward approach to check for uniformity and continuity in the seal.

- Air Leak Test: This method measures the integrity of the seal by detecting leaks using pressurized air.

VII. Key Parameters of the Laboratory Heat Sealer

Here are the main parameters that affect the performance of a Laboratory Heat Sealer:

- Sealing Temperature: Ranges from ambient to 300°C, with a deviation of ±0.2°C.

- Sealing Time: Adjustable from 0.1 seconds to 9999 hours.

- Sealing Pressure: From 0.15 to 0.7 MPa, ensuring a wide range of settings for different materials.

- Seal Jaw Size: 330 mm x 10 mm (L x W).

- Power Requirements: AC 220V, 50Hz.

- Gas Pressure: Operates with 0.7 MPa gas pressure, connected via a PU hose.

FAQs

What materials can be tested with a Laboratory Heat Sealer?

Answer: The Laboratory Heat Sealer can test a variety of materials, including films, laminates, thermoplastics, and composite materials used in packaging for food, pharmaceuticals, and medical devices.Why is ASTM F2029 important in heat seal testing?

Answer: ASTM F2029 outlines the procedures and parameters for creating laboratory heat seals and measuring their strength, ensuring that packaging meets quality and safety standards.How can I determine the optimal sealing temperature for my material?

Answer: The optimal sealing temperature depends on the material’s properties. Start by referencing ASTM F2029, then experiment with the temperature settings on your laboratory heat sealer to achieve the best results.What happens if the seal is too weak or too strong?

Answer: A weak seal can lead to leaks and contamination, while an overly strong seal can be difficult for consumers to open. It’s important to adjust temperature, pressure, and time to achieve the ideal seal strength.What safety features does the Laboratory Heat Sealer offer?

Answer: The Laboratory Heat Sealer is equipped with features like anti-scald covers and both manual and foot switch operation to enhance operator safety during testing.