GHS Gradient Laboratory Heat Sealer

- Standard: ASTM F2029

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing and more.

- Customization: Available for special testing requirements and automation transformations

Gradient Laboratory Heat Sealer Principle

Gradient Laboratory Heat Sealer operates by applying heat, pressure, and time to a sample of packaging material. These three variables—heat, pressure, and time—are adjustable, allowing users to simulate a wide range of packaging conditions. The ability to control these parameters is crucial for manufacturers who need to optimize sealing processes for different materials.

One of the key features of advanced Gradient Laboratory Heat Sealers is the gradient sealing function. A Gradient Heat Sealer allows for multiple temperature settings to be tested simultaneously across a single sample. This capability speeds up the testing process, enabling manufacturers to determine the optimal sealing parameters without the need for separate tests for each condition.

Gradient Laboratory Heat Sealer Technical Features

The success of any Gradient Laboratory Heat Sealer relies on its precision and stability in controlling heat, pressure, and time. Key technical features include:

Temperature Control: Equipped with a high-precision P.I.D. (Proportional-Integral-Derivative) controller, the heat sealer ensures accurate and stable temperature regulation. The upper and lower sealing jaws are made of aluminum, which minimizes heat loss and guarantees even temperature distribution across the sealing surface.

Sealing Pressure: A three-way guided sealing bar ensures uniform pressure distribution across the material, leading to consistent and reliable seals.

Customizable Jaws: Depending on the application, users can customize the dimensions, shapes, and patterns of the sealing jaws to meet specific material requirements.

Safety Features: User safety is prioritized with anti-scald covers and options for manual or foot-switch operation, protecting operators from accidental burns.

Gradient Laboratory Heat Sealer Test Process and Method

Sample Preparation

Before beginning the test, a sample of the material—whether it’s a film, laminate, or flexible barrier material—is placed between the upper and lower heated sealing jaws of the Laboratory Heat Sealer.

Heat Sealing Process

Once the sample is secured, the sealing jaws are preheated to the desired temperature. The upper sealing jaw, driven by a gas cylinder, is pressed down onto the material, applying the necessary pressure. The material remains under pressure for a predetermined amount of time to allow the heat to transfer and create a strong seal. Once the time has elapsed, the jaws release the sample, and the test is complete.

Multi-Station Testing

In the case of a Gradient Heat Sealer, the test can be performed with varying temperature settings at different locations on the sample. This simultaneous multi-station testing accelerates the process and ensures the most efficient use of time and resources. Manufacturers can test the sealability of a material under different conditions without conducting separate tests for each one.

ASTM F2029: Heat Sealing Standards

The ASTM F2029 standard outlines the practices for making laboratory heat seals to determine the heat sealability of flexible barrier materials. This standard is essential for ensuring that heat seals meet quality expectations, and it provides guidelines on:

Test Procedures: ASTM F2029 describes the specific procedures for creating heat seals in a laboratory environment. These seals are then tested for strength and integrity to determine if they meet the necessary performance criteria.

Seal Strength Measurement: The standard provides methods for measuring seal strength, a critical parameter for ensuring the longevity and effectiveness of packaging materials.

By adhering to ASTM F2029, manufacturers can ensure that their heat-sealing processes meet industry standards for quality and reliability.

Key Specifications

| Sealing Temp. | Ambient~250℃ |

| Temp. Gradient | ≤20℃ |

| Deviation | ±0.2℃ |

| Sealing Time | 0.1S~9999S |

| Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws(mm) | U:40*10 5PCS/L:330 1PCS |

| Gas Input | 0.7 MPa with Ф6 mm Pipe |

| Power | AC 220V 50Hz |

Heat Seal Evaluation Techniques

Once the sealing process is complete, the heatsealability of the material can be evaluated using several techniques. The most common methods include:

Air Leak Testing: This technique assesses whether any air leaks through the sealed area, which would indicate a weak or incomplete seal.

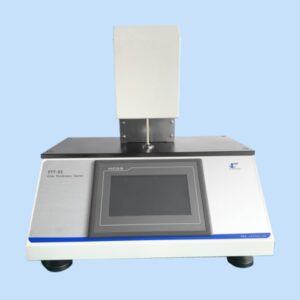

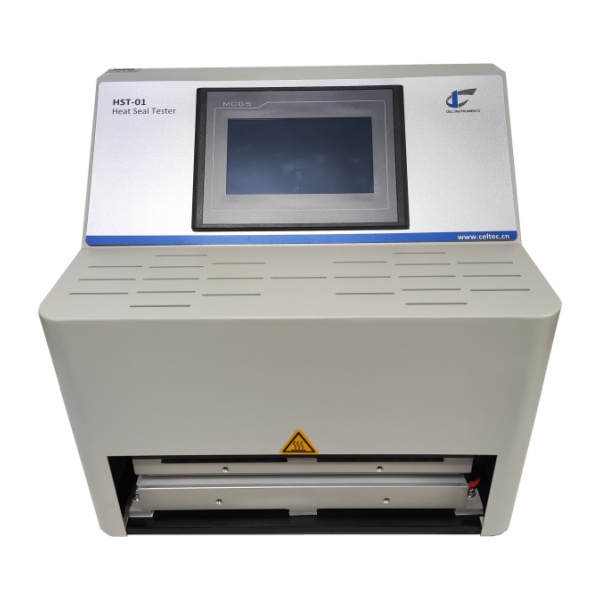

Relative Models

HST-01 Laboratory Heat Seal Tester

Best Laboratory Heat Seal Tester compliant with ASTM F2029. Precision testing for packaging, medical devices, pharmaceuticals, textiles, and more.