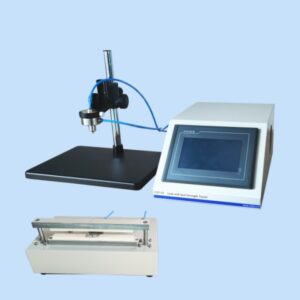

PER-01 Bottle Perpendicularity Tester

- Standard: ISO 9008:1991

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements

I. Introduction to Bottle Perpendicularity Tester

Perpendicularity is a critical attribute in bottle manufacturing, ensuring that bottles stand upright and function correctly during filling, capping, and labeling processes. The Bottle Perpendicularity Tester is a specialized instrument designed to measure the perpendicularity of bottles with high precision, ensuring they meet industry standards and perform reliably in various applications.

Industries such as packaging, food, beverages, pharmaceuticals, and cosmetics rely heavily on bottle perpendicularity testing to ensure product quality and safety. Accurate perpendicularity measurements help prevent product defects, reduce material wastage, and maintain compliance with stringent industry regulations.

II. Product Description

Key Features of Bottle Perpendicularity Tester

Technical Features:

- Convenient Probe Adjustment: Simple and hassle-free fine-tuning of the measuring probe ensures that measurements are accurate and consistent.

- Exceptional Reading Precision: Achieving high-resolution readings with accuracy down to 0.001mm, the tester provides reliable data for quality control.

- Consistent Sample Rotation: Ensuring a steady and stable rotation of the sample, which is crucial for accurate perpendicularity measurement.

- Adherence to Sample Specifications: The tester meets specific sample requirements for measuring both diameter and height, accommodating a wide range of bottle sizes.

- Optional Data Export to PC Excel: Providing the choice to export data to PC Excel enhances data management and analysis capabilities, making it easier to record and review test results.

III. Technical Specifications

| Sample Diameter | 5mm-145mm (or as required) |

| Test Rage | 0-12.7mm (or as required) |

| Division value | 0.01 or 0.001mm(optional) |

| Measurable Height | 15mm-300mm (or as required) |

IV. Test Methods

1. Testing Procedure

Preparation of the Bottle Sample:

- Ensure the bottle is clean and free of any obstructions that might affect the measurement.

- Calibrate the tester according to the Cell Instruments’ instructions.

Mounting the Bottle on the Tester:

- Secure the bottle in the holder, ensuring it is stable and properly aligned.

Steps Involved in Conducting the Test:

- Initiate the rotation mechanism to ensure consistent sample movement.

- Adjust the measuring probe to the appropriate position.

- Start the test and record the perpendicularity measurements.

Reading and Interpreting the Results:

- The tester will display the measurements, which can be interpreted against industry standards or specific requirements.

2. Benefits of Regular Perpendicularity Testing

- Ensuring Product Quality and Safety: Accurate perpendicularity ensures that bottles function correctly, preventing leaks, spills, and other defects.

- Compliance with Industry Standards: Regular testing ensures compliance with industry standards such as ISO 9008:1991, maintaining credibility and customer trust.

- Reducing Material Wastage and Production Costs: Identifying defects early in the production process reduces material wastage and associated costs.

V. ISO 9008:1991 Glass bottles — Verticality — Test method

1. Introduction to ISO 9008:1991

Purpose and Scope of ISO 9008:1991:

- ISO 9008:1991 provides guidelines for perpendicularity testing, ensuring consistent and reliable measurements in industrial applications.

2. Key Requirements of ISO 9008:1991

- Specifications for Perpendicularity Testing: Detailed criteria for the perpendicularity measurement process.

- Calibration and Maintenance of Testing Instruments: Regular calibration and maintenance to ensure measurement accuracy and instrument reliability.

3. How the Tester Meets ISO 9008:1991 Standards:

- The Bottle Perpendicularity Tester is designed to meet all specifications outlined in ISO 9008:1991, ensuring precise and reliable measurements.

- The tester includes features such as high-precision probes, stable sample rotation, and data export capabilities to maintain compliance with the standard.

Brief Description of the Test Process Described in the Standard:

- Sample Preparation: Ensure the bottle sample is clean and free from any defects or contaminants.

- Calibration: Calibrate the testing instrument according to the manufacturer’s instructions to ensure accuracy.

- Mounting the Sample: Securely mount the bottle on the tester, ensuring it is properly aligned.

- Measurement: Conduct the perpendicularity test by measuring the deviation from the vertical axis at specified points on the bottle. Rotate the sample as needed to obtain comprehensive measurements.

- Recording Results: Document the measurements accurately, ensuring all data is recorded according to the standard’s guidelines.

- Analysis and Interpretation: Analyze the results to determine if the bottle meets the required perpendicularity specifications. Use the data to identify any deviations and take corrective actions if necessary.

VI. Applications and Industries

1. Packaging Industry

Importance of Perpendicularity in Bottle Packaging:

- Ensures bottles stand upright and are easily handled during production.

2. Food and Beverage Industry

Ensuring Product Integrity and Shelf Appeal:

- Proper perpendicularity ensures bottles are visually appealing and functionally reliable on store shelves.

3. Pharmaceutical Industry

Compliance with Regulatory Standards:

- Ensures that bottles meet stringent pharmaceutical standards for safety and quality. Ensuring Patient Safety:

- Accurate perpendicularity prevents leaks and contamination, safeguarding patient health.

4. Other Relevant Industries

- Textiles, Adhesives, Electronics, etc.: Various industries benefit from accurate perpendicularity measurements to ensure product quality and functionality.

VII. Customization Options

Tailored Solutions for Specific Testing Needs:

- We offer customized solutions to meet unique testing requirements across different industries.

Examples of Custom Projects Completed:

- Custom testers for non-standard bottle shapes and sizes.

VIII. FAQ

Ensures bottles stand upright and function correctly, preventing defects and ensuring product quality.

The tester features high-precision probes and stable sample rotation to provide accurate and reliable measurements.

Yes, the tester is designed to accommodate a wide range of bottle sizes and shapes, ensuring versatility in testing.

Compliance with ISO 9008:1991 enhances credibility, ensures consistent quality, and meets regulatory requirements, which can lead to increased customer trust and market competitiveness.

We provide comprehensive after-sales support, including technical assistance, maintenance services, and training programs to ensure you get the most out of your bottle perpendicularity tester.

Reference

ISO 9008:1991 Glass bottles — Verticality — Test method