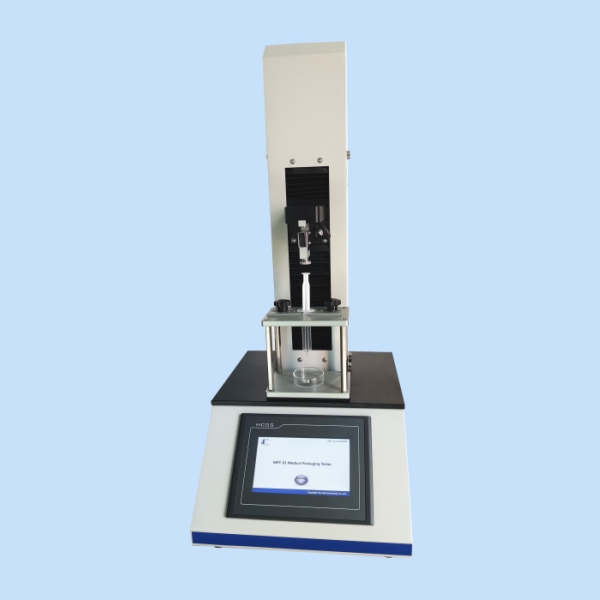

MST-01 Syringe Plunger Force Tester

- Standard: USP 382, ISO 7886-1, ISO 8537, ISO 11040-4, ISO 11608-5, DIN 13097-4

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

MST-01 Syringe Plunger Force Tester measures the force required to move the plunger within a syringe barrel.

I. Introduction of Syringe Plunger Force Tester

1. Brief of Syringe Plunger Force Test

In the realm of medical and pharmaceutical industries, the accuracy and reliability of syringes are paramount. The syringe plunger force test is a critical evaluation process that measures the force required to move the plunger within a syringe barrel. This test ensures that syringes operate smoothly and deliver medication effectively, without requiring excessive force that could compromise patient safety.

2. Syringe Plunger Force Tester – Cell Instruments

Cell Instruments offers a state-of-the-art Syringe Plunger Force Tester designed to meet the rigorous demands of medical device testing. Our tester is engineered to provide precise measurements of the force needed to push the plunger of a syringe, ensuring that each syringe meets the high standards of performance and safety required in medical and pharmaceutical applications.

II. Technical Specifications

| MST-01 Syringe Plunger Force Tester | |

| Test Range | 50N (or as required) |

| Stroke | 200mm (without clamp) |

| Test Speed | 1~500mm/min |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~220V |

III. Key Features and Benefits of the Tester

1. Reliability and Precision of Measurements

Our Syringe Plunger Force Tester is renowned for its high accuracy and reliability (with PLC control). The instrument provides precise measurements of the force required to move the syringe plunger, ensuring that every test result is accurate and dependable.

2. Ease of Use and User-Friendly Interface

The tester is designed with the user in mind. Its intuitive interface and straightforward operation make it accessible for users of all skill levels, from lab technicians to research scientists.

3. Robust Construction and Long-Term Durability

Built with high-quality materials, the Syringe Plunger Force Tester is designed for longevity and consistent performance. Its robust construction ensures it can withstand the demands of frequent testing in various industrial environments.

4. Comprehensive Customer Support and Service

Cell Instruments is committed to providing exceptional customer support. Our team of experts is available to assist with installation, training, and ongoing maintenance, ensuring that our clients get the most out of their investment.

IV. Test Methods

1. Testing Process

The testing process with the Syringe Plunger Force Tester involves several key steps:

- Calibration: Calibrate the tester according to the specific syringe size and type.

- Setup: Choose the testing item. Secure the syringe in the testing fixture of the device.

- Testing: Initiate the test to measure the force required to move the plunger. The instrument records the force exerted throughout the plunger’s movement.

- Data Collection: The tester collects and displays real-time data, providing an immediate visual representation of the results.

2. Explanation of Data Interpretation and Result Analysis

Interpreting the data from the Syringe Plunger Force Tester involves analyzing the force-distance curve generated during the test. Key metrics include:

- Initial Force: The force needed to start moving the plunger.

- Maximum Force: The highest force recorded during the plunger’s movement.

- Sustained Force: The force required to maintain the plunger’s movement.

By analyzing these metrics, users can determine whether a syringe meets the necessary performance standards. The data can be exported for further analysis and reporting, ensuring comprehensive documentation of each test.

V. Applications

Medical Device Testing

Our Syringe Plunger Force Tester is indispensable for testing medical devices, ensuring that syringes perform reliably and safely.

Pharmaceutical Industry Applications

In the pharmaceutical industry, the tester verifies that syringes used for drug delivery are up to standard, ensuring patient safety and effective medication administration.

Quality Control in Manufacturing

Manufacturers rely on our tester to maintain high quality control standards, ensuring each syringe batch meets regulatory requirements and industry standards.

Research and Development Settings

In R&D environments, the tester supports the development of new syringe designs and technologies, providing crucial data to inform product improvements.

VI. Push Plunger Force Test in ISO 7886-1

ISO 7886-1 Annex E Test Method for the Determination of Forces Required to Operate the Piston

The ISO 7886-1 standard outlines the test methods for determining the forces required to operate the syringe piston. Annex E specifically addresses the push plunger force test:

- Objective: To measure the force required to move the plunger through the syringe barrel at a controlled speed.

- Procedure: The syringe is placed in the tester, and the plunger is moved at a predetermined rate. The force exerted is recorded throughout the process.

- Parameters: Initial, maximum, and sustained forces are measured and compared against standard limits.

- Significance: Ensuring syringes meet these force requirements is crucial for safety and functionality, providing confidence in their performance in clinical settings.

VII. Customization and Automation Solutions

Customization Options for Unique Testing Requirements

Cell Instruments offers customization options to meet specific testing needs. Whether it’s adapting the tester for different syringe sizes or integrating additional features, we provide tailored solutions to meet diverse requirements.

Automation Transformation Services to Enhance Efficiency

To further enhance productivity, we offer automation transformation services. Automating the testing process not only increases efficiency but also improves consistency and reduces human error, ensuring reliable and repeatable results.

VIII. FAQ

Measuring syringe plunger force is vital for ensuring the syringe operates smoothly and safely, meeting quality and regulatory standards, and providing reliable performance in medical andpharmaceutical applications.

The tester follows the procedures outlined in ISO 7886-1, particularly Annex E, which specifies the method for measuring the force required to operate the syringe plunger, ensuring compliance with international standards.

Yes, the Syringe Plunger Force Tester is designed to be compatible with a wide range of syringe sizes, from 1 mL to 50 mL, and can be customized for other sizes if needed.

The tester provides real-time data on the initial, maximum, and sustained forces required to move the syringe plunger. This data can be exported for detailed analysis and reporting.

Cell Instruments offers comprehensive support, including installation, training, maintenance, and customization services to ensure clients maximize the benefits of their Syringe Plunger Force Tester.