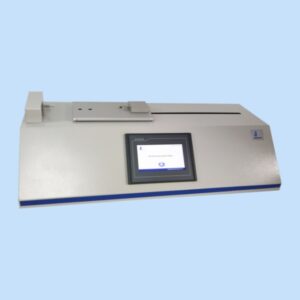

LTT-01 Loop Tack Tester

- Standard: ASTM D6195, PSTC-16, FINAT No. 9

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

I. Introduction to the Loop Tack Tester

The loop tack test is used to measure the tack force or strength of a pressure-sensitive adhesive (PSA) according to ASTM D6195, FINAT FTM 9 and PSTC 16. It helps evaluate the adhesive’s ability to bond quickly and strongly to a substrate, which is crucial in packaging, labeling, and other adhesive applications.

Loop Tack Testing Process

- A loop is formed from the test material with the adhesive-coated side facing the substrate or a stainless steel plate.

- The ends of the loop are clamped together in an upper grip.

- The loop is pressed onto the surface, compressing the adhesive.

- The loop is then pulled away, and the adhesive gradually debonds from the substrate, measuring the force required to break the bond.

The loop tack test provides valuable information about the immediate adhesive strength of PSAs. It is particularly important for evaluating adhesives in products that require quick bonding, such as tapes, labels, and medical devices.

II. Technical Features

- Precision and Accuracy: Our Loop Tack Tester is equipped with high-precision sensors that deliver accurate and consistent measurements. This precision ensures that even the smallest variations in adhesive tack are detected, providing reliable data for quality control and product development.

- User-Friendly Interface: The tester features an intuitive control panel and user-friendly software, making it accessible for operators of all skill levels. The interface allows for easy setup, execution, and analysis of tests, streamlining the testing process.

- Versatility: Designed to test a wide range of adhesive materials, the Loop Tack Tester can handle various tape and adhesive products. This versatility makes it suitable for multiple applications, from simple packaging tapes to complex medical adhesives.

- Customization Options: Recognizing that different industries may have unique testing requirements, our Loop Tack Tester can be customized. We offer special testing configurations and automation options to meet specific needs, ensuring optimal performance for every application.

III. Technical Specifications

The Loop Tack Tester boasts a range of technical specifications tailored to provide precise and reliable tack measurements:

| Test Range | 200N (or others) |

| Speed Range | 1-500 mm/m |

| Stroke | 200mm |

| Sample Size | 125mm*25mm |

| Power | AC 110~220V, 50/60HZ |

IV. Standard for Loop Tack Test Method

- ASTM D6195 Standard Test Methods for Loop Tack

- FINAT FTM 9 Loop tack measurement

- PSTC 16 Test Methods for Pressure Sensitive Adhesive Tapes

V. Custom Support

Cell Instruments offers tailored support to meet your specific testing needs. Whether you require customization of the tester or specialized test configurations, our team is here to assist.

Technical Support: Our experienced technical support team is available to provide guidance and troubleshooting. We ensure that your Loop Tack Tester operates smoothly and delivers accurate results.

Training and Documentation: We provide comprehensive training programs to help your team effectively use the Loop Tack Tester. Additionally, detailed user manuals and documentation are available to support ongoing operations.

FAQs

The loop tack test measures the pressure-sensitive tack property of adhesives by quantifying the force required to detach an adhesive loop from a substrate.

Its ensures standardization in tack testing, providing reliable and repeatable results that are accepted across various industries.

Yes, the tester is versatile and can accommodate a wide range of adhesive materials, making it suitable for diverse applications.

We offer customization for special testing requirements, including different test configurations and automation solutions to meet specific needs.