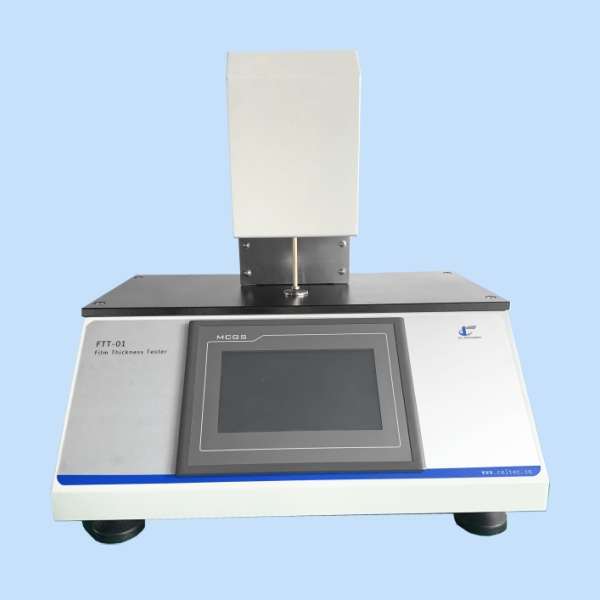

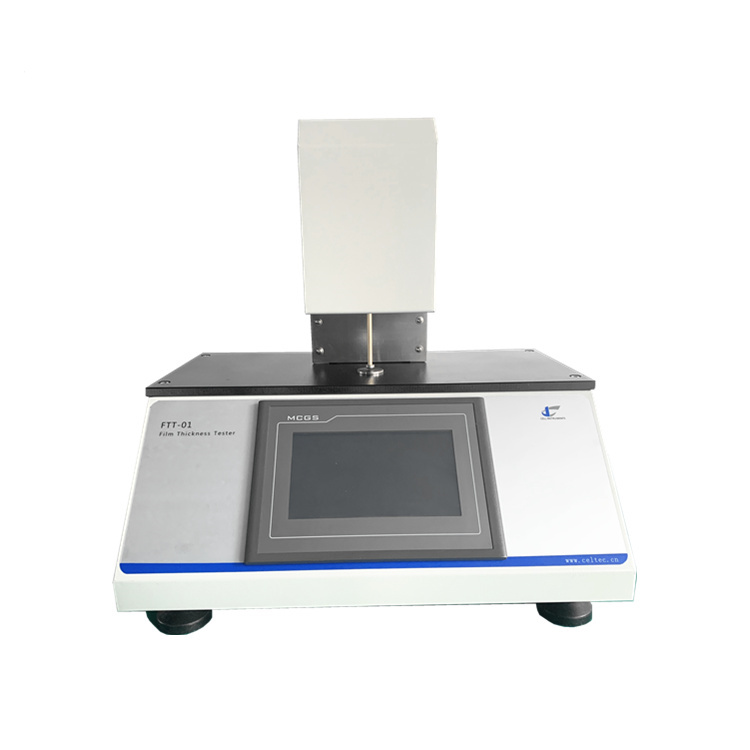

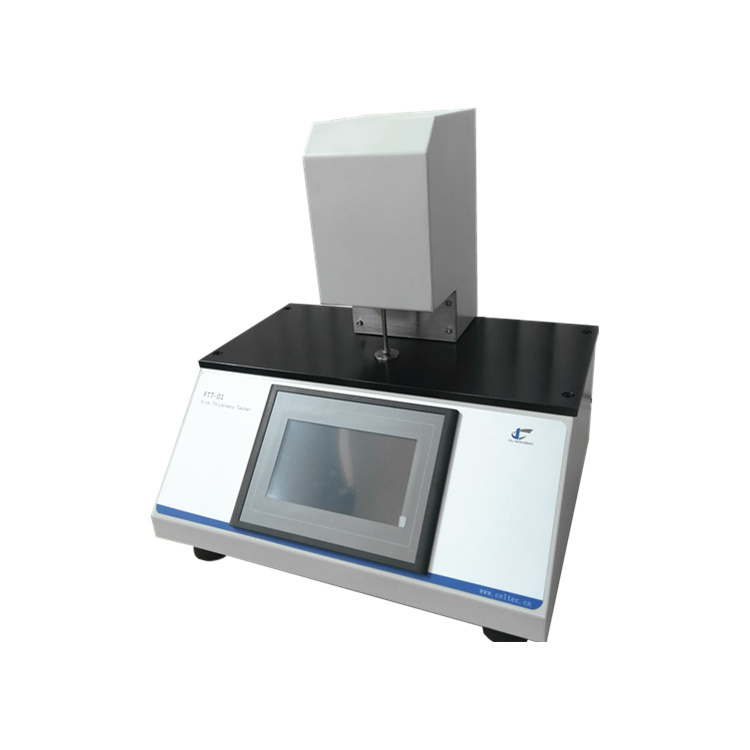

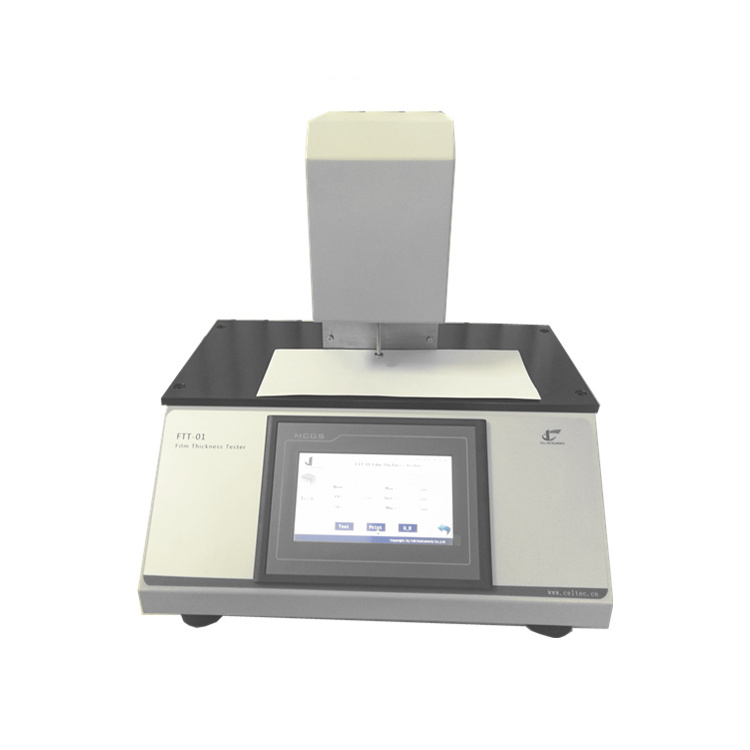

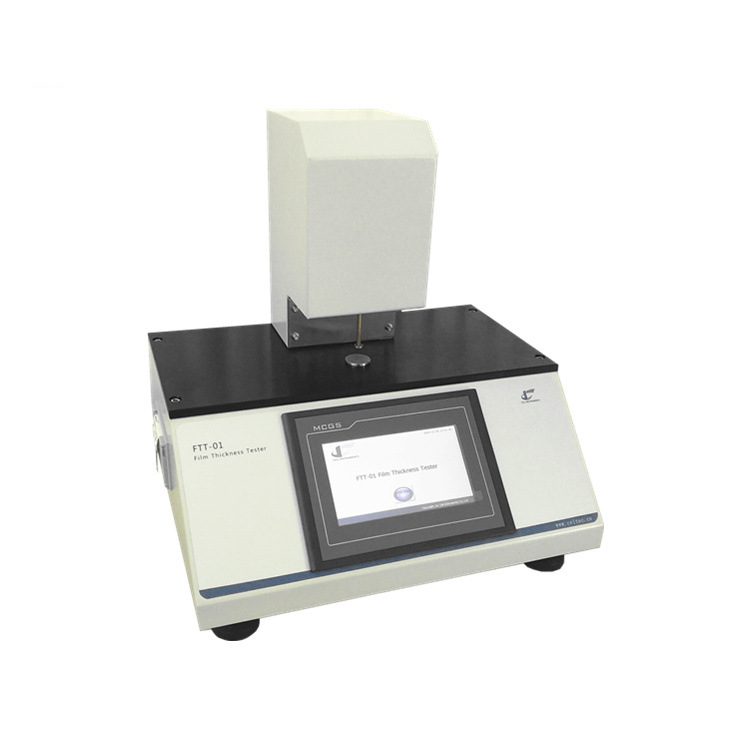

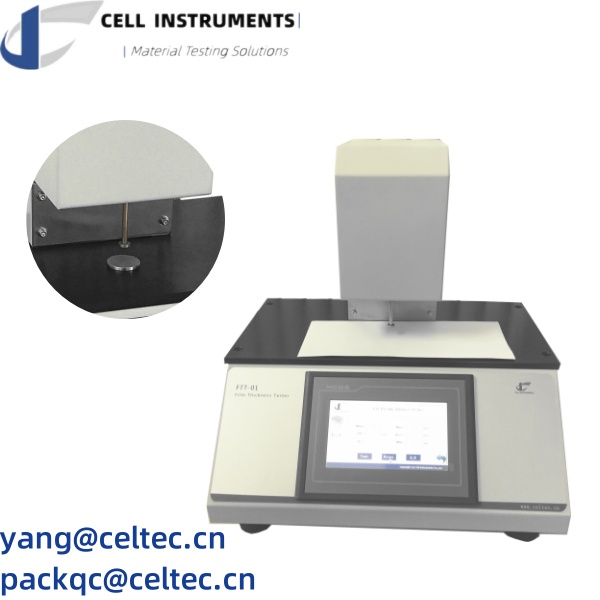

FTT-01 Benchtop Film Thickness Tester

- Standard: ASTM D1777, ASTM D374, ISO 3034, ISO 4593, ISO 534

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

I. Introduction to Benchtop Film Thickness Tester

1. Brief Description of the Instrument

The Benchtop Film Thickness Tester is an advanced precision instrument designed to measure the thickness of various films, foils, papers, and cardboard materials. Utilizing the displacement method, this tester provides highly accurate measurements essential for quality control and research and development.

2. Key Features and Benefits

- High Precision and Accuracy: Ensures reliable measurements with minimal deviation.

- Intuitive Software and User-Friendly Interface: Controlled by a PLC and operated through an HMI touch screen, the device is easy to navigate.

- Versatility: Compatible with a wide range of materials, including films, foils, paper, and cardboard.

- Customizable Settings: Tailored options for special testing requirements.

- Durability and Reliability: Built to withstand rigorous usage in various industrial environments.

3. Applications

The Benchtop Film Thickness Tester is ideal for use in:

- Packaging Industry: Ensuring consistent material thickness for optimal packaging performance.

- Food and Beverage Industry: Maintaining the integrity of packaging materials.

- Medical and Pharmaceutical Industry: Verifying compliance with stringent regulatory standards.

- Adhesives and Textiles: Quality assurance in material thickness.

- Plastics and Electronics: Ensuring product reliability and performance.

- Quality Inspection Agencies: Providing precise and consistent measurements for various materials.

II. Technical Specifications

1. Measurement Principle

The Benchtop Film Thickness Tester uses the displacement method, where a sensor detects the distance between the film surface and a reference point. This non-destructive method ensures high accuracy without damaging the sample.

2. Technical Details

| Test Range | 0~2mm(Customization available) |

| Resolution | 0.1 μm |

| Standard Measure Head | Hemispherical type |

| Optional Measure Head (flat foot) | 50 mm² , 17.5±1 KPa (for film) 200 mm² , 50±1 KPa (for paper) |

| Power | AC 110~220V |

III. Key Features and Benefits

1. High Precision and Accuracy

The instrument’s high precision and accuracy are achieved through advanced sensor technology and robust construction. This ensures that each measurement is reliable and reproducible, making it essential for quality control processes.

2. Intuitive Software and User-Friendly Interface

Equipped with a PLC and HMI touch screen, the Benchtop Film Thickness Tester is straightforward to operate. The automatic presser foot lifting feature enhances ease of use, while real-time displays of maximum, minimum, average, and standard deviation measurements facilitate quick data analysis. Additionally, the instrument can store test results and micro-print them for documentation. An RS232 port with optional software compatibility allows for seamless data transfer, and both manual and automatic sample feeding options cater to different user needs.

3. Versatility

The tester’s compatibility with a variety of materials, including films, foils, paper, and cardboard, makes it a versatile tool for numerous industries. This flexibility ensures that the instrument can meet diverse testing requirements without the need for multiple devices.

4. Customizable Settings

With options for special testing requirements, the Benchtop Film Thickness Tester can be tailored to meet unique needs. This customization enhances the instrument’s applicability across various testing scenarios and industries.

5. Durability and Reliability

Constructed from high-quality materials, the tester is designed for long-term use. Its durability ensures consistent performance over time, making it a reliable tool for industrial applications.

IV. Testing Methods

1. Overview of ISO 4593

ISO 4593 specifies the test methods for determining the thickness of plastic films and sheets. Adhering to this international standard ensures that measurements are accurate, reproducible, and consistent across different laboratories and applications.

2. Testing Procedure

To perform a ISO 4593 thickness test using the displacement method, follow these steps:

- Sample Preparation: Ensure the sample is clean and free from wrinkles or folds.

- Calibration of the Instrument: Use standard calibration blocks to set the instrument.

- Conducting the Measurement: Place the sample on the testing platform, and the sensor will measure the thickness.

- Analyzing and Interpreting Results: The HMI screen displays the maximum, minimum, average, and standard deviation values in real-time.

V. Applications and Case Studies

1. Packaging Industry

Accurate thickness measurements are crucial for packaging materials to ensure durability and cost-effectiveness. This instrument helps manufacturers maintain consistent quality.

2. Medical and Pharmaceutical Industry

In the medical field, precise thickness measurements are essential for compliance with regulatory standards. This tester ensures materials meet the required specifications.

3. Adhesives and Textiles

For adhesives and textiles, uniform thickness is vital for product performance. The Benchtop Film Thickness Tester provides the necessary accuracy for quality assurance.

4. Other Industries

The instrument is also valuable in plastics and electronics, where material thickness can affect product performance and reliability.

VI. Customization

1. Special Testing Requirements

The Benchtop Film Thickness Tester offers customization options to cater to unique testing needs. Whether it’s adjusting the measurement range or integrating with automated systems, the instrument can be tailored to meet specific requirements.

2. Customization Options

Options include additional software features, automated sample feeding, and enhanced data storage capabilities. These customizations ensure the tester can handle a wide variety of applications.

VII. FAQ

The measurement range is from 0.1 mm to 10 mm, making it suitable for a variety of materials.

The displacement method involves a sensor detecting the distance between the film surface and a reference point, providing accurate thickness measurements without damaging the sample.

Yes, the Benchtop Film Thickness Tester offers various customization options, including software enhancements and automated sample feeding.

Yes, the instrument adheres to ISO 4593 standards, ensuring accurate and consistent measurements.

Industries such as packaging, food, medical, pharmaceutical, adhesives, textiles, plastics, and electronics can all benefit from the precise measurements provided by this tester.