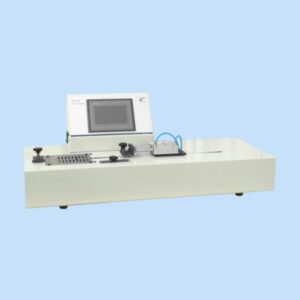

COF-01 Coefficient of Friction Testing Equipment

- Standard: ASTM D1894, ISO 8295

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

I. Introduction of Coefficient of Friction Testing Equipment

(1) Overview of Coefficient of Friction (CoF) Testing

The coefficient of friction (CoF) is a fundamental parameter in material testing that quantifies the resistance encountered when two surfaces slide against each other. CoF testing is crucial for ensuring the quality, safety, and performance of various products across multiple industries, including packaging, medical devices, pharmaceuticals, adhesives, textiles, and more. Accurate CoF measurements help in understanding material behavior, optimizing manufacturing processes, and ensuring compliance with industry standards.

(2) About Cell Instruments Coefficient of Friction Testing Equipment

At Cell Instruments, we offer state-of-the-art Coefficient of Friction Testing Equipment designed to meet the diverse needs of our clients. Our equipment is engineered for precision, reliability, and versatility, ensuring that you obtain consistent and accurate results every time.

Key Features and Benefits:

- High Precision: Our equipment is designed to deliver precise CoF measurements with minimal variability.

- User-Friendly Interface: Easy-to-use controls and intuitive software make operation simple, even for first-time users.

- Customization Options: We offer tailored solutions to meet specific testing requirements.

- Robust Design: Built for durability, our CoF testing machines require minimal maintenance, providing long-term reliability.

II. Technical Specifications and Features

Technical Specifications

| Load Cell | 5 N(or as required) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Sled Size | 63.5mm*63.5mm (or as required) |

| Test Speed | 100mm/min (ISO), 150mm/min (ASTM) |

| Dimensions | 540mm(L)*380mm(W)*240mm(H) |

| Weight | NW 21kg |

| Power | 110~220V 50/60Hz |

Technical Features

(1) Precision and Reliability

Ensuring consistent and accurate results is at the heart of our CoF testing equipment. Advanced sensors and calibration systems guarantee high precision, while the robust build ensures long-term reliability and minimal maintenance needs.

(2) Versatility and Customization

Our equipment is designed to adapt to a wide range of materials and testing scenarios. Whether you are testing smooth films, rough textiles, or adhesive surfaces, our Coefficient of Friction Testing Equipment provide accurate results. We also offer customization options to address unique testing requirements, providing tailored solutions that integrate seamlessly into your existing processes.

(3) User Experience and Support

Ease of use is a key feature of our CoF testing equipment. The intuitive interface allows for straightforward operation, while our comprehensive training programs ensure that your team can effectively utilize the equipment. Additionally, we provide exceptional technical support and customer service to assist you with any issues or questions.

III. Test Methods

(1) Principles of CoF Testing

CoF testing involves measuring the frictional forces between two surfaces. This is typically divided into static friction (the force required to initiate movement) and kinetic friction (the force required to maintain movement). Proper sample preparation and conditioning are essential to ensure accurate and repeatable results.

(2) Sample Preparation and Conditioning

- Sample Size: Standard size is typically 63.5 mm x 63.5 mm(standard), but this can vary depending on the specific test requirements.

- Conditioning: Samples should be conditioned at 23°C and 50% relative humidity for at least 48 hours prior to testing.

(3) Testing Procedure

- Calibration: Ensure the equipment is calibrated according to the manufacturer’s instructions.

- Sample Placement: Secure the sample on the test sled and the counterpart material on the test bed.

- Testing: Initiate the test by moving the sled at a constant speed. Record the static and kinetic friction forces.

- Data Analysis: Analyze the results using the provided software to determine the CoF values.

IV. Standards for CoF Testing

(1) ASTM D1894

ASTM D1894 is a widely recognized standard for measuring the CoF of plastic film and sheeting. It provides a consistent methodology to ensure comparability of results across different laboratories and industries.

Detailed Test Method According to ASTM D1894:

- Sample Preparation: Samples are cut into strips and conditioned as specified.

- Test Setup: The film is placed on a horizontal plane while the sled, covered with the same or different material, is pulled across the plane at a constant speed.

- Measurements: The forces required to initiate and maintain movement are recorded to determine the static and kinetic CoF.

Requirements and Specifications:

- Equipment Calibration: Regular calibration is essential for accuracy.

- Test Speed: Typically set at 150 mm/min.

- Environmental Conditions: Testing should be conducted at controlled temperature and humidity levels.

(2) ISO 8295

ISO 8295 is an international standard for determining the CoF of plastic films and sheeting. It ensures uniform testing procedures and results consistency on a global scale.

Detailed Test Method According to ISO 8295:

- Sample Preparation: Similar to ASTM D1894, samples are prepared and conditioned.

- Test Setup: The sample is placed on a flat surface, and a sled with a specified weight is pulled across it at a constant speed.

- Measurements: Static and kinetic friction forces are measured to calculate the CoF.

Requirements and Specifications:

- Test Speed: Set between 100 to 300 mm/min, typically 100 mm/min.

- Sled Weight: Specified according to the standard.

- Environmental Conditions: Tests should be performed under controlled conditions to ensure repeatability.

V. Applications and Industry Use Cases

Packaging Materials

In the packaging industry, CoF testing is crucial to ensure materials do not stick together excessively or slide apart too easily, affecting the integrity and usability of packaging.

Medical and Pharmaceutical

For medical devices and pharmaceutical packaging, controlling the CoF is vital to ensure safety, functionality, and compliance with regulatory standards.

Textiles and Adhesives

In textiles, the CoF affects fabric hand feel and performance. For adhesives, it determines bonding strength and ease of application.

VI. FAQ

CoF testing measures the resistance to sliding motion between two surfaces. It is essential for understanding material behavior and ensuring product quality across various industries.

CoF testing ensures that packaging materials do not stick together excessively or slide apart too easily, maintaining the integrity and usability of the packaging.

Our equipment uses advanced sensors and calibration systems to deliver precise and consistent CoF measurements. Regular maintenance and calibration further ensure long-term accuracy.

Yes, we offer customization options to meet specific testing requirements, ensuring our equipment fits seamlessly into your workflow.

Industries such as packaging, medical devices, pharmaceuticals, textiles, adhesives, and electronics benefit from CoF testing by ensuring product quality, performance, and compliance with standards.