ASTM D1894

Test Process: In the Coefficients of Friction Test, a film specimen is secured on a flat surface, while a sled covered with a similar or different material is placed on top. The test begins with the sled being pulled at a uniform speed, and the force required to move it is recorded. This force is used to calculate both the static and kinetic coefficients of friction, giving insight into the ease with which materials slide over each other.

Test Result Interpretation: The test results are expressed as coefficients of friction: static (before movement starts) and kinetic (once movement is ongoing). A higher coefficient means greater friction, indicating that the material will resist sliding more, while a lower coefficient means smoother movement. These values are essential for industries concerned with packaging, handling, and transportation.

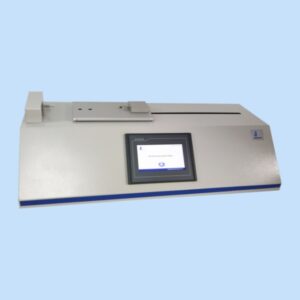

Instrument Requirements: The test requires a friction tester capable of applying a consistent pulling force and measuring the static and kinetic friction accurately. The instrument should be calibrated to meet ASTM D1894 standards, ensuring precise force measurement and speed control during the test.

Showing all 3 results