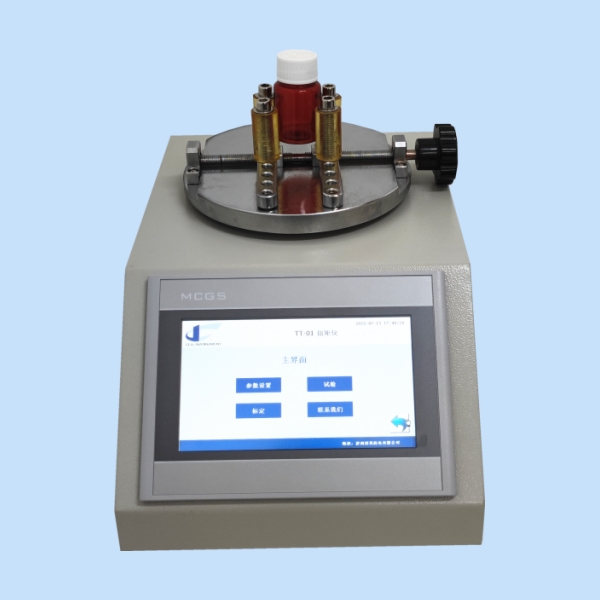

TT-01 Manual Cap Torque Tester

- Standard: ASTM D2063, ASTM D3198, ASTM D3474, GB/T17876, BB/T0025, BB/T0034

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, and more.

- Customization: Available for special testing requirements and automation transformations

I. Introduction to the Manual Cap Torque Tester

The Manual Cap Torque Tester is a highly reliable device used to measure the torque required to open and lock caps on various types of packaging, such as medicine bottles, PET bottles, spout bags, and flexible tube packages. In packaging industries, understanding and controlling cap torque is critical. If the torque is too high, the container can be difficult to open for the consumer, or it may damage the packaging. On the other hand, insufficient torque can result in product leakage or compromised packaging integrity during transportation.

By providing precise measurements, the Manual Cap Torque Tester helps manufacturers meet industry standards and ensure customer satisfaction. Its use is widespread in industries like food, beverages, pharmaceuticals, and personal care products, where packaging integrity and ease of use are paramount.

II. Application of the Manual Cap Torque Tester

Testing Cap Torque for Packaging Quality

The Manual Cap Torque Tester is essential in quality control, especially in high-volume production environments. This device measures the force required to open or lock caps, enabling manufacturers to optimize production lines to ensure consistent packaging quality. Whether used for testing caps on medicine bottles, PET bottles, or flexible tubes, the tester plays a pivotal role in ensuring that the torque values applied during the packaging process are accurate and meet product-specific standards.

For example, in the pharmaceutical industry, the correct torque is vital for ensuring that medicine bottles remain securely closed during transportation but can be easily opened by consumers. In the beverage industry, accurate cap torque ensures product freshness and safety while avoiding spillage or leaks.

III. Key Technical Features of the Manual Cap Torque Tester

1. High Precision and Stability

The Manual Cap Torque Tester is known for its precision and stability, making it an ideal choice for rigorous quality control environments. It offers a high degree of accuracy with a resolution of 0.001 Nm, ensuring that even the smallest variations in torque values are captured.

2. Flexible Measurement Units

One of the standout features of the Manual Cap Torque Tester is its ability to display torque measurements in multiple units, including Kgf.cm, N.cm, daN.cm, Inch.lbs, and N.m. This flexibility makes it suitable for a wide range of applications, from pharmaceuticals to food and beverage packaging. The device also allows for peak value retention, ensuring that operators can easily record the highest torque force applied during testing.

3. User-Friendly Design

With a simple, user-friendly design, the Manual Cap Torque Tester offers an intuitive interface that is easy to operate. The tester is equipped with a touch screen for easy operation and a PLC-controlled system that ensures industrial-level stability during testing. This combination of precision, stability, and ease of use makes the device a reliable tool in any production setting.

IV. Test Methods for the Manual Cap Torque Tester

Cap Torque Testing Procedure

The process of testing with the Manual Cap Torque Tester is straightforward but vital for ensuring packaging quality. The sample container is first securely fastened onto the device’s clamp. Then, the cap is manually opened or closed, while the tester records the torque force required. A sensor connected to the clamp measures the torque, which is then displayed on the screen in the desired unit.

The tester’s ability to measure both opening and locking forces makes it ideal for use across a variety of packaging types. After the test, the peak value is automatically retained for easy data recording, ensuring that the highest torque applied during the test is accurately captured.

V. Compliance with Major Standards

The Manual Cap Torque Tester is designed to meet several international standards, making it a reliable tool for quality control in various industries. The following standards outline the requirements for cap torque testing and packaging integrity:

- ASTM D2063: This standard specifies the methods for testing the torque of plastic caps and closures.

- ASTM D3198: Defines the methods for determining the torque retention of caps and closures, ensuring that they remain properly sealed over time.

- ASTM D3474: Covers environmental testing of packaging materials, including torque testing under different conditions.

- GB/T 17876: A Chinese standard for cap torque testing, ensuring compliance with regional packaging requirements.

- BB/T 0025 & BB/T 0034: Industry-specific standards for cap testing, particularly for food and beverage packaging.

VI. Main Technical Specifications

| Test Range | 10 Nm (or as required) |

| Accuracy | 1% FS |

| Resolution | 0.001 Nm |

| Clamp Range | Φ5mm~φ170mm |

| Power AC | 110~220V |

FAQs

Q1: What is a Manual Cap Torque Tester used for?

A: The Manual Cap Torque Tester is used to measure the opening and locking forces of caps on bottles, jars, and other containers to ensure packaging quality and safety.

Q2: Why is cap torque testing important?

A: Cap torque testing ensures that the right amount of force is applied when sealing or opening containers, preventing product leakage, ensuring consumer safety, and enhancing user experience.

Q3: What industries benefit most from cap torque testing?

A: Cap torque testing is essential in industries such as food and beverages, pharmaceuticals, personal care products, and any industry where packaging integrity is important.

Q4: What standards does the Manual Cap Torque Tester comply with?

A: The tester complies with several standards, including ASTM D2063, ASTM D3198, ASTM D3474, GB/T 17876, and BB/T 0025 & BB/T 0034.

Q5: Can the tester measure both opening and locking forces?

A: Yes, the Manual Cap Torque Tester can measure both the force required to open a cap and the force needed to lock it, making it a versatile tool for packaging quality control.

Related Model

MCT-01 Motorized Cap Torque Tester