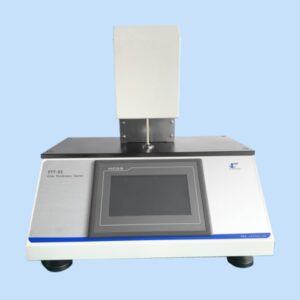

FPT-01 Friction Peel Tester

- Standard: ISO 8295, ASTM D1894, TAPPI T816, ISO 8510-2, ASTM D4917, ASTM D3330, TAPPI T549

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

The Friction Peel Tester is an advanced instrument designed to assess two critical properties in material testing: the Coefficient of Friction (COF) and peeling force. These tests are essential for industries involved in packaging, medical devices, pharmaceuticals, textiles, adhesives, and beyond. Ensuring that products meet friction and peel standards guarantees functionality, safety, and performance. The Friction Peel Tester offers a precise, versatile, and reliable solution for both COF tests and peel tests, enabling manufacturers to improve their quality control processes and develop superior products.

Key Features and Benefits of the Friction Peel Tester

The Friction Peel Tester combines dual testing capabilities in one efficient device, making it ideal for a wide range of materials, including plastic films, paper, textiles, and adhesive products. It allows users to perform the following:

COF Testing: Measures both static and kinetic coefficients of friction. Static COF determines the friction between two materials when they are at rest, while kinetic COF measures the friction when materials are in motion. This distinction is crucial for understanding how materials interact with each other during different stages of use.

Peeling Force Testing: Evaluates the force required to separate two bonded layers, such as adhesive tapes, release liners, and medical adhesives. This test helps assess the ease of separation and ensures product reliability.

The tester is controlled via a PLC system with an intuitive HMI touch screen interface. It offers precision control, thanks to a ball lead screw mechanism, which ensures consistent speed and displacement during tests. The real-time display of test data allows for immediate analysis, ensuring that users can adjust production parameters or improve product design based on the results.

Test Methods of the Friction Peel Tester

Coefficient of Friction (COF) Test

COF tests are critical for determining how two surfaces interact when they come into contact, particularly in the packaging industry where materials like plastic films, woven bags, or paperboard must move smoothly through machinery without sticking or tearing.

In a COF test, the sample material is placed on a flat surface, with a sled of a known weight dragged across it at a controlled speed. The tester measures the force required to initiate and maintain the sled’s movement, providing both static and kinetic COF values. These values help manufacturers determine if materials are too sticky (high COF) or too slippery (low COF), both of which can affect product performance.

Peeling Force Test

The peeling force test is equally important for applications like packaging seals, adhesive labels, and medical devices. It measures the force required to peel one layer from another. The process involves applying a small force to peel a material layer (like adhesive tape or protective film) from its base and recording the force over the length of the separation.

The Friction Peel Tester allows precise control over test parameters such as initial and tail portions, both of which influence the peel strength. The ability to analyze peeling force across these sections helps manufacturers optimize their adhesive products for ease of use while maintaining secure bonds.

Compliance with International Standards

The Friction Peel Tester adheres to multiple international standards, ensuring that it meets the requirements of various industries:

ISO 8295: This standard specifies methods for determining the COF of plastic films and sheets. By complying with this standard, manufacturers can guarantee that their products meet global requirements for packaging materials.

ASTM D1894: This widely used standard outlines procedures for testing the COF of plastic films and coated substrates, a critical aspect in the packaging industry.

TAPPI T816: Provides a method for measuring the frictional properties of paper and paperboard, ensuring that these materials will perform as expected during handling and processing.

ISO 8510-2: Governs peel adhesion testing for adhesives. This standard ensures that adhesives maintain consistent peel strength, crucial for applications like medical tapes and packaging seals.

ASTM D4917: This standard focuses on the frictional properties of woven fabrics, providing manufacturers in the textile industry with reliable testing methods.

ASTM D3330: Specifies methods for testing the peel adhesion of pressure-sensitive tapes, helping manufacturers ensure that tapes can be removed without damaging surfaces or leaving residue.

TAPPI T549: Details peel adhesion testing for release liners and adhesive products, ensuring that these materials meet quality expectations in packaging and labeling.

Technical Specifications

| Force Range | 5N, 10N, or 30N (or others) |

| Accuracy | 0.5 F.S. |

| Sled | 200±1g (or as required) |

| Stroke | 500mm |

| Test Speed | 1~500mm/min |

| Power | 110~220V 50/60Hz |

Why Choose Cell Instruments Friction and Peel Tester?

The Friction Peel Tester stands out for its versatility, precision, and compliance with international standards. Whether testing friction or peel strength, this tester provides manufacturers with reliable data to improve product quality and ensure industry compliance.

FAQ

Q1: What is the difference between static and kinetic COF?

A: Static COF measures the resistance when two materials are at rest, while kinetic COF measures the resistance once they are moving. Both are important for understanding material interaction during various stages of use.

Q2: Which materials can be tested with the Friction Peel Tester?

A: The tester can handle a wide range of materials, including plastic films, paper, woven fabrics, adhesive tapes, and more, making it suitable for industries like packaging, textiles, and medical devices.

Q3: How does the peel test work on adhesive products?

A: The peel test measures the force needed to separate two bonded layers. This helps determine the adhesive strength and ensures that products can be peeled easily without damaging the underlying surface.

Q4: What are the main standards the tester complies with?

A: The tester adheres to key standards such as ISO 8295 (plastic films), ASTM D1894 (COF of plastic substrates), TAPPI T816 (friction in paperboard), and ASTM D3330 (adhesive tape peel strength), among others.

Q5: Can the Friction Peel Tester be customized for specific needs?

A: Yes, the device can be customized with different sled weights, force ranges, and testing speeds to meet specific testing requirements, making it highly adaptable for various applications.

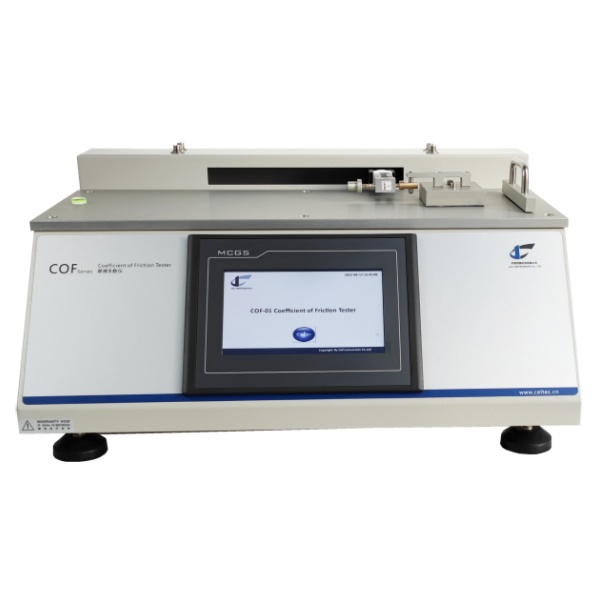

Relative Models

COF-01 Coefficient of Friction Tester

Designed to ASTM D1894/ISO 8295 standard

and meet the diverse needs of our clients.