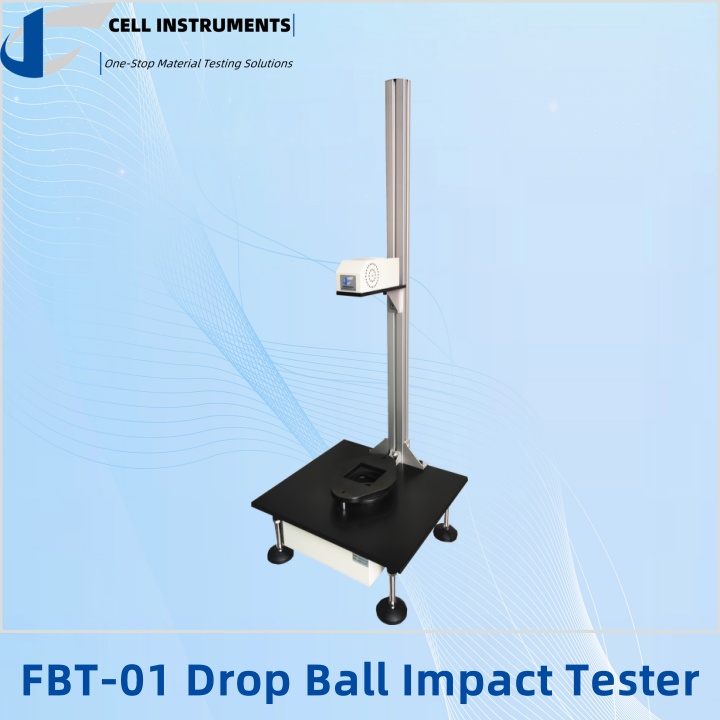

FBT-01 Drop Ball Impact Tester

- Standard: ASTM D1709, ISO 7765-1, JIS K7124-1, GB/T 9639.1

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

Introduction of Drop Ball Impact Tester

The Drop Ball Impact Tester is a specialized instrument designed to evaluate the impact resistance of various materials, such as films, foils, paper, and thin plates. This device provides accurate results for materials subjected to sudden shock or impact forces. By simulating real-world impacts, this tester helps manufacturers and researchers assess the durability and resilience of materials.

Key Features of the Drop Ball Impact Tester

- Precision Control: Incorporates advanced PLC control for industrial-grade stability.

- Customizable Impact Parameters: Adjustable impact height and various ball sizes/masses for diverse test scenarios.

- User-Friendly Interface: Operated via an HMI touch screen, with easy operation through manual or foot switch controls.

- Secure Sample Clamping: Pneumatic mechanisms ensure stable and secure sample positioning.

- Automatic Ball Release: Equipped with electromagnetic suspension for controlled and precise impact delivery.

- Data Output and Analysis: Results displayed in multiple units, with optional advanced software for in-depth analysis.

- Versatile Application: Suitable for testing thin materials like plastic films, sheets, and composites of less than 2mm thickness.

Test Methods Overview

The Drop Ball Impact Tester uses a steel ball of known mass, which is released from a predetermined height to create a controlled impact on the test specimen. The material’s ability to resist damage—such as cracking, deformation, or rupture—is analyzed by observing the resulting effects.

The main variables in the test include:

- Drop Height: Adjustable between 300mm to 600mm (extendable based on requirements).

- Ball Size and Mass: Available in sizes like 23mm, 25mm, 28.6mm, and more.

- Impact Energy: The impact energy generated by the ball hitting the sample is analyzed to evaluate the material’s performance under shock loads.

Comply with ASTM D1709 and ISO 7765-1

ASTM D1709: Impact Resistance of Plastic Film

This standard defines a method to determine the impact resistance of plastic films using a free-falling dart. The Drop Ball Impact Tester aligns closely with ASTM D1709, ensuring compliance for manufacturers seeking to measure film toughness under sudden impact.

ISO 7765-1: Determination of Impact Resistance of Plastic Films and Sheets

ISO 7765-1 specifies the methodology for testing the impact resistance of thermoplastic films and sheets by means of a free-falling object. The Drop Ball Impact Tester meets the criteria set forth by ISO 7765-1, providing a reliable means to assess material durability in accordance with international standards.

Factors Influencing Test Results

- Drop Height: The greater the height, the higher the impact energy, leading to potentially more damage.

- Ball Size and Mass: Heavier and larger balls produce stronger impacts, simulating more severe conditions.

- Material Properties: Different materials react uniquely to impacts, with thinner, more flexible materials typically showing greater deformation.

Applications of the Drop Ball Impact Tester

The Drop Ball Impact Tester is widely used across industries to ensure material quality and durability:

- Packaging: Testing film and plastic sheets for packaging to ensure they can withstand rough handling during transport.

- Medical Devices: Assessing the toughness of medical packaging materials.

- Pharmaceuticals: Evaluating packaging that protects sensitive pharmaceutical products.

- Textiles and Paper: Determining the impact strength of paper and thin textiles.

- Daily Chemicals: Testing materials used in personal care product containers and packaging.

Why Choose Cell Instruments Drop Ball Impact Tester?

The Drop Ball Impact Tester provides an effective, repeatable way to measure material resistance under impact. It helps manufacturers in quality control, material selection, and product development by ensuring that their materials meet the stringent demands of real-world conditions.

FAQ

What is the importance of impact resistance testing?

Impact resistance testing helps ensure that materials can withstand sudden forces, reducing the risk of product failure in the field.What materials can be tested using the Drop Ball Impact Tester?

The tester is suitable for films, foils, paper, and plastic sheets with a thickness of less than 2mm.How does the Drop Ball Impact Tester comply with ASTM D1709 and ISO 7765-1?

The instrument adheres to the testing methods outlined in these standards, ensuring accurate and reliable impact resistance testing for plastic films and sheets.Can the test height and ball size be adjusted?

Yes, both the drop height and ball size/mass can be customized to meet specific testing requirements.How is the test data recorded and analyzed?

Test results are displayed in various units and can be further analyzed using optional professional software for in-depth reporting.

Relative Models

FDT-01 Dart Impact Tester

Measure the impact resistance of plastic films

ASTM D1709, ISO 7765-1, JIS K7124-1, GB/T 9639.1