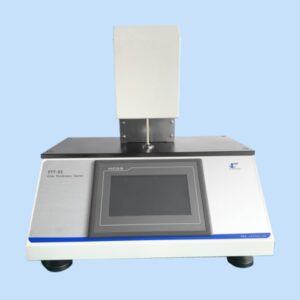

CLRT-01 Automatic Beverage Carbonation Tester

- Standard: ASTM F1115

- Manufacturer: Cell Instruments

- Applications: Packaging materials, containers, and more.

- Customization: Available for special testing requirements and automation transformations

Maintaining consistent carbonation levels in beverages is a crucial factor in the beverage industry. From sparkling water to soft drinks, the amount of carbon dioxide (CO2) in a beverage directly affects its sensory experience, including taste, texture, and fizziness. The Beverage Carbonation Tester is a vital tool used to measure the carbonation levels of beverages, ensuring that they meet quality standards and consumer expectations.

I. What is a Beverage Carbonation Tester?

The Beverage Carbonation Tester is an automated instrument designed to measure the CO2 content in carbonated beverages. It accurately assesses the level of carbonation, a critical factor that affects the flavor and texture of drinks. The tester is widely used in quality control processes within beverage manufacturing industries, allowing producers to maintain consistent carbonation levels across their products.

By automating the carbonation testing process, the Beverage Carbonation Tester minimizes human error and enhances efficiency.

II. Why is Carbonation Testing Important?

Carbonation refers to the amount of dissolved CO2 gas in a liquid. In beverages, this gas creates the characteristic bubbles and fizz that many consumers love. Too much carbonation can cause drinks to be overly fizzy, while too little carbonation can make them flat. Ensuring the right balance of CO2 is essential to maintain product quality and consistency.

Testing for carbonation not only helps maintain the sensory qualities of a beverage but also ensures compliance with safety and quality regulations. For instance, over-carbonated beverages can become unsafe due to excessive internal pressure within containers, potentially leading to bursting bottles or cans. Accurate carbonation testing helps avoid these issues.

III. Beverage Carbonation Tester: Key Features

The Beverage Carbonation Tester is designed to automate the traditional manual methods of measuring carbonation. Here are some of its main features:

Automated Testing Process

The tester automates the entire testing process, including piercing the bottle cap, releasing pressure, shaking the bottle, and recording temperature and pressure data. This automation not only improves accuracy but also significantly reduces the time required for testing.Precise Control and Customization

The Beverage Carbonation Tester allows users to customize shaking parameters, including shaking speed and duration. This flexibility ensures that the tester can be adapted for various beverage types, including sodas, beer, and sparkling water.Accurate Measurement

Equipped with high-precision pressure and temperature sensors, the tester guarantees accurate results. It records the stabilized pressure and temperature of the beverage, which are used to calculate the CO2 content.Leak-Proof Design

The tester is designed with anti-leak mechanisms to ensure that no CO2 escapes during the testing process, which is essential for maintaining the integrity of the results. It is suitable for both bottles and cans, making it versatile for various beverage packaging formats.

IV. ASTM F1115 Compliance

The ASTM F1115 standard is the official guideline for determining carbonation levels in beverages. This standard outlines the methodology and procedures for accurately measuring the volume of carbon dioxide in packaged beverages. The Beverage Carbonation Tester complies fully with ASTM F1115, ensuring that manufacturers follow internationally recognized testing methods.

ASTM F1115 specifies the relationship between the pressure and temperature of the beverage and the resulting CO2 content. The Beverage Carbonation Tester automates this process, calculating the carbonation level based on the measurements of stabilized pressure (in MPa) and temperature (in degrees Celsius). By complying with ASTM F1115, manufacturers can ensure that their carbonation testing processes are reliable and consistent across different batches of production.

V. Test Methods and Process Overview

The testing process with the Beverage Carbonation Tester involves several key steps:

Piercing the Bottle Cap

The tester starts by piercing the bottle cap to allow CO2 to escape. This step is critical for measuring the internal pressure of the beverage.Pressure Release and Shaking

After piercing the cap, the vent valve is opened to release some pressure, which is then followed by shaking the bottle vigorously for about 40 seconds. This shaking ensures that the CO2 in the beverage is evenly distributed.Pressure and Temperature Measurement

Once shaking is complete, the system records the stabilized pressure and measures the liquid temperature using precise sensors. These two values are crucial for calculating the CO2 volume.Result Calculation

Using the data from the pressure and temperature readings, the tester calculates the CO2 volume and presents the results. These results are essential for manufacturers to assess whether the carbonation levels are within the desired range.

The automated nature of the Beverage Carbonation Tester significantly improves efficiency, allowing manufacturers to test multiple samples in a short amount of time. Additionally, the ability to customize test parameters makes the tester adaptable for a wide range of beverages.

VI. Significance of Beverage Carbonation Testing

Carbonation testing is vital for maintaining product quality, consistency, and safety. It helps ensure that beverages are neither under-carbonated nor over-carbonated, both of which can affect product taste and safety. By accurately measuring CO2 levels, manufacturers can optimize their formulations and provide products that align with consumer expectations.

Moreover, compliance with ASTM F1115 and other industry standards ensures that beverage manufacturers meet regulatory requirements, protecting both consumers and brand reputations. Regular carbonation testing helps manufacturers avoid costly product recalls and maintain their market position.

FAQs

Q1: What types of beverages can be tested using the Beverage Carbonation Tester?

A1: The Beverage Carbonation Tester can be used to test a variety of carbonated beverages, including sodas, beer, sparkling water, and energy drinks.

Q2: How does the Beverage Carbonation Tester ensure accuracy in measuring carbonation?

A2: The tester is equipped with high-precision pressure and temperature sensors, ensuring accurate and reliable results. It follows the standardized ASTM F1115 testing method.

Q3: Can the shaking speed and time be adjusted for different beverage types?

A3: Yes, the tester allows users to customize the shaking parameters, including speed and duration, to accommodate different beverage formulations.

Q4: Does the Beverage Carbonation Tester comply with industry standards?

A4: Yes, the tester complies with ASTM F1115, the industry standard for measuring carbonation levels in beverages, ensuring accuracy and consistency in test results.

Q5: Is the tester suitable for both bottles and cans?

A5: Yes, the tester is designed to accommodate both bottles and cans, making it versatile for various packaging types in the beverage industry.

Related Model

CLRT-02