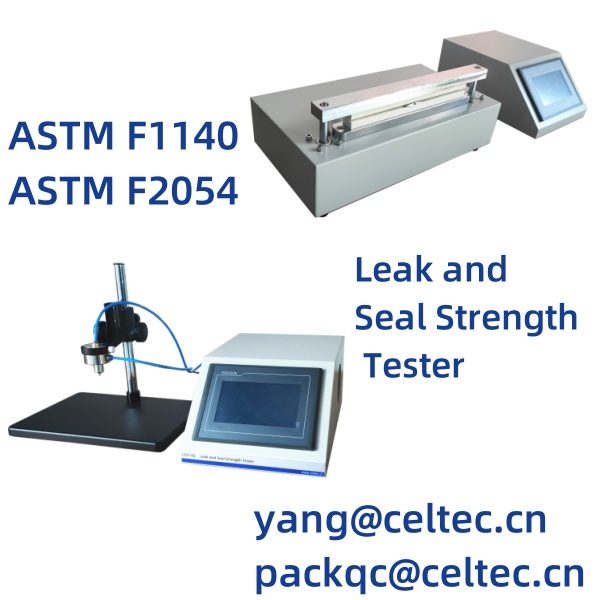

LSST-01 Pouch Burst Tester

- Standard: ASTM F1140, ASTM F2054

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements

I. Introduction to the Pouch Burst Tester

1. Overview of the Pouch Burst Tester

The Pouch Burst Tester is an advanced instrument designed to measure the burst strength of flexible packaging materials, ensuring their integrity and durability. This crucial piece of equipment is used to test the resistance of pouches and flexible packaging to internal pressurization, providing accurate and reliable data critical for quality control and R&D purposes.

2. Definition and Importance in Various Industries

The Pouch Burst Tester is vital in industries where packaging integrity is crucial, such as food, medical, pharmaceutical, adhesives, and textiles. For instance, in the medical field, ensuring that device packaging is robust enough to protect its contents from contamination is essential. Similarly, in the food industry, packaging must withstand various stresses to maintain product freshness and safety.

3. Key Features and Benefits

- High Accuracy: Precision sensors ensure reliable results.

- Customization: Tailored testing solutions for specific requirements.

- User-Friendly Interface: Intuitive software simplifies operation and data analysis.

- Automation Capabilities: Enhances efficiency and repeatability of tests.

- Compliance with Standards: Adheres to ASTM F2054 and ASTM F1140, ensuring industry-standard quality.

II. Applications of the Pouch Burst Tester

The Pouch Burst Tester is utilized across a variety of sectors:

- Medical Devices: Ensuring packaging integrity to protect medical devices from contamination.

- Pharmaceuticals: Verifying the robustness of packaging for medications.

- Food and Beverages: Testing the durability of food pouches and beverage containers to maintain product quality.

- Adhesives and Textiles: Assessing the strength of adhesive bonds and textile materials.

Specific Examples:

- Medical Device Packaging: Ensuring sterile barrier systems remain intact under pressure.

- Food Pouches: Testing to ensure pouches can withstand the rigors of transportation and storage without bursting.

- Pharmaceutical Packages: Verifying that blister packs and other forms of pharmaceutical packaging are secure.

III. Technical Specifications and Features

Detailed Technical Specifications:

| Test Range | 0~600KPa |

| Sample Width | 300mm (standard) |

| Inflating Head | Φ4mm |

| Compressed Air | 0.4~0.7MPa (Prepared by user) |

| Power | 110~220V 50/60Hz |

Unique Features:

- PLC-Controlled Unit: Ensures industrial-level stability and precision with programmable logic control (PLC), making it suitable for rigorous testing environments.

- User-Friendly HMI Touch Screen: Simplifies operation through an intuitive human-machine interface (HMI) touch screen, providing easy access to all test settings and functions.

- Automatic Data Management: Facilitates automatic test result statistics and storage, streamlining data analysis and record-keeping.

- Versatile Fixture Compatibility: Accommodates a wide range of fixtures, allowing testing of various package forms such as open packages (three-side-seal), closed packages, doy packs, tubes, sealed trays, and cups.

- Multiple Test Modes: Offers three distinct test modes—burst, creep, and creep to failure—enabling comprehensive evaluation of package integrity under different conditions.

- Personalized Settings: Allows customization of sensitivity and threshold settings to tailor tests to specific requirements and standards.

- Wide Pressure Range: Capable of operating up to 600 KPa, with options for customization to meet unique testing needs.

- Customizable Programming: Features customizable programming to address specific testing requirements, ensuring versatility and adaptability for diverse testing scenarios.

IV. Testing Methods

1. Overview of Testing Methods Supported

The Pouch Burst Tester supports a variety of testing methods designed to evaluate the burst strength and integrity of flexible packaging.

2. Explanation of Burst Testing and Its Significance

Burst testing measures the pressure at which a pouch or package will fail, providing critical information on its strength and durability. This data is essential for ensuring packaging will protect its contents under real-world conditions.

3. ASTM F2054 and ASTM F1140 Standards

These standards specify the procedures for burst testing, ensuring consistency and reliability in test results.

V. Introduction to ASTM Standards

1. Detailed Explanation of ASTM F2054 Standard

Scope: Covers burst testing of flexible packages by internal pressurization. Test Procedure: Involves sealing the package and applying air pressure until the package bursts. Equipment Requirements: Requires a calibrated burst tester capable of applying and measuring pressure accurately. Reporting Results: Includes recording burst pressure and any failure mode observations.

2. Detailed Explanation of ASTM F1140 Standard

Scope: Describes internal pressurization failure resistance testing for unrestrained packages. Test Procedure: Similar to F2054, with variations to accommodate different package types. Equipment Requirements: Similar apparatus requirements, emphasizing precision and accuracy. Reporting Results: Detailed documentation of test conditions, burst pressure, and observed behaviors.

VI. Operation and Calibration

Step-by-Step Guide to Operating the Pouch Burst Tester:

- Setup: Secure the sample in the testing chamber.

- Calibration: Ensure the machine is calibrated to the required standards.

- Testing: Initiate the test, gradually increasing internal pressure until the sample bursts.

- Data Collection: Record the burst pressure and analyze the data.

- Maintenance: Regularly inspect and maintain the equipment to ensure accurate results.

VII. Customization Options for Specific Testing Needs

The Pouch Burst Tester can be customized to meet unique testing requirements, including:

- Custom Fixtures: Designed for various package shapes and sizes.

- Software Modifications: Tailored to specific data collection and analysis needs.

- Automation: Integration with automated systems for high-throughput testing.

VIII. Benefits of Using the Pouch Burst Tester

- Quality Assurance and Compliance: Ensures packaging meets industry standards and regulations.

- Cost-Effectiveness: Reduces the risk of product failures and recalls.

- Improved Product Reliability and Safety: Enhances the durability and safety of packaged goods.

- Enhanced Research and Development Capabilities: Facilitates the development of new materials and packaging designs.

IX. FAQ

The primary purpose is to measure the burst strength of flexible packaging, ensuring its integrity and durability under pressure.

The tester adheres to ASTM F2054 and ASTM F1140 standards, which outline the procedures and requirements for burst testing flexible packages.

Yes, it offers customization options, including custom fixtures, software modifications, and integration with automated systems.

Industries such as medical, pharmaceutical, food, beverages, adhesives, and textiles benefit significantly by ensuring the quality and safety of their packaging.

Regular calibration is recommended to maintain accuracy and reliability, typically every 6 to 12 months depending on usage and industry standards.

Reference

ASTM F2054 Standard Test Method for Burst Testing of Flexible Package Seals Using Internal Air Pressurization Within Restraining Plates

ASTM F1140 Standard Test Methods for Internal Pressurization Failure Resistance of Unrestrained Packages