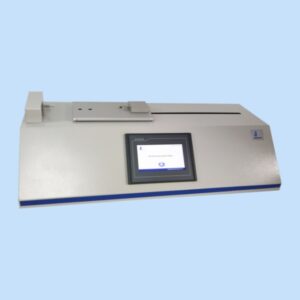

Needle Penetration Test Equipment for ISO 7864 Testing

- Standard: ISO 7864

- Manufacturer: Cell Instruments

- Applications: medical device materials, pharmaceutical testing, and more.

- Customization: Available for special testing requirements and automation transformations

Needle penetration test equipment is a critical tool for evaluating the sharpness and performance of medical needles. This testing is essential in ensuring compliance with industry standards, such as ISO 7864 testing, which governs the quality of sterile hypodermic needles. The test measures key parameters such as penetrability test force and drag force to assess the needle’s effectiveness in piercing biological materials.

Key of ISO 7864 Testing

ISO 7864 is the standard for hypodermic needles used in medical applications. It specifies requirements for performance, safety, and penetrability test procedures to ensure patient safety and ease of use. The penetration force and drag force are measured as the needle moves through a standardized substrate, replicating real-life injection scenarios.

Test Principle

The needle penetration test equipment evaluates the force required to insert a needle into a substrate at a controlled speed. The force gauge records resistance throughout penetration and withdrawal, providing insights into:

Initial penetration force – the force required to pierce the material.

Drag force region – the resistance as the needle moves through the substrate.

Penetration depth – the displacement of the needle as force is applied.

How the Penetrability Test is Conducted

To ensure consistency and repeatability, the penetrability test follows these standardized steps:

Sample Preparation – The test samples and substrates are conditioned for at least 24 hours at laboratory conditions:

Temperature: 18°C to 28°C

Humidity: 25%RH to 75%RH

Test Setup – The needle is mounted on the force measurement apparatus, ensuring alignment perpendicular to the substrate.

Penetration Process – The needle moves at a controlled speed to pierce the substrate until the required penetration depth is achieved.

Force Measurement – The equipment records force data during insertion and withdrawal.

Result Calculation – Mean and standard deviation of penetration and drag forces are computed based on the sample size.

Key Features of High-Quality Needle Penetration Test Equipment

For reliable ISO 7864 testing, needle penetration test equipment should include:

High-precision load cell to measure penetration and drag forces.

Adjustable penetration depth for versatile testing applications.

Automated alignment system to prevent misalignment errors.

Real-time data acquisition for accurate analysis.

User-friendly interface for simplified operation and reporting.

Main Parameter

Main Parameter – Needle penetration test equipment

Technical Feature

Technical Feature – Needle penetration test equipment

Choosing the Right Needle Penetration Test Equipment

Selecting suitable needle penetration test equipment involves evaluating:

Testing accuracy and precision – Essential for reliable compliance.

Equipment versatility – Should accommodate different needle sizes and materials.

Software integration – For seamless data analysis and storage.

Durability and maintenance – Ensures long-term performance with minimal downtime.

Needle penetration testing is a fundamental part of medical device quality control. High-precision needle penetration test equipment ensures compliance with ISO 7864 testing and enhances the overall safety and effectiveness of medical needles. By selecting the right testing instruments, manufacturers can improve product performance and patient experience while meeting stringent regulatory standards.