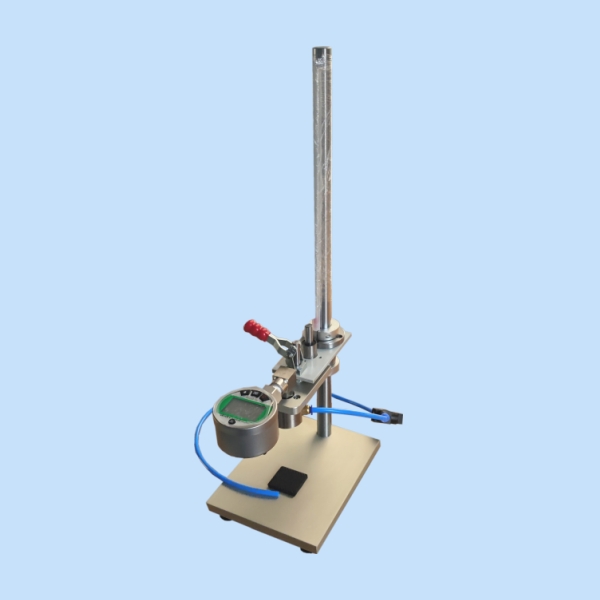

CLRT-02 Manual Carbonation Tester

- Standard: ASTM F1115

- Manufacturer: Cell Instruments

- Applications: Packaging materials, containers, and more.

- Customization: Available for special testing requirements and automation transformations

I. Introduction to the Carbonation Tester

The Carbonation Tester is an essential instrument for measuring the carbonation levels of beverages such as soft drinks, beer, and sparkling water. Ensuring the correct amount of carbon dioxide (CO2) in beverages is critical to maintaining product quality and meeting industry standards. Excess carbonation can cause containers to burst, while insufficient carbonation impacts taste and customer satisfaction. Accurate measurement of CO2 volume ensures consistency in production and compliance with quality control standards.

At Cell Instruments, we specialize in manufacturing high-precision materials testing instruments, including carbonation testers. Our solutions are designed to help industries like food and beverage, packaging, pharmaceuticals, and quality inspection agencies perform reliable testing for carbonation levels.

II. Importance of Carbonation Testing

Carbonation is a critical component in the beverage industry, affecting both the flavor and texture of the final product. CO2 is responsible for the fizz and mouthfeel of carbonated drinks, and any deviation from the desired levels can affect the overall quality. The Carbonation Tester ensures that manufacturers maintain the correct CO2 levels throughout the production process, minimizing variations that could lead to poor customer experiences or product recalls.

Using a carbonation tester also helps prevent container damage caused by over-pressurization. Excessive carbonation in bottled products can increase internal pressure, leading to leakage or even bursting. By accurately measuring carbonation levels, manufacturers can ensure product safety, reduce waste, and uphold quality standards.

III. Applications of the Carbonation Tester

The Carbonation Tester is widely used across several industries, including:

- Beverages: Soft drinks, beer, sparkling water, and other carbonated drinks.

- Food Packaging: Ensuring proper CO2 levels in canned or bottled food products.

- Pharmaceuticals: Testing CO2 content in medical packaging that requires pressurization.

IV. Testing Methods of the Carbonation Tester

The testing procedure for carbonation involves measuring both the pressure and temperature of the beverage to determine the CO2 volume. The Carbonation Tester works by following a simple, step-by-step process:

Piercing the Bottle Cap: The first step is to pierce the bottle cap using the tester’s durable, quenching piercing head. This ensures that the bottle remains sealed after piercing, preventing leakage.

Opening the Vent Valve: After piercing, the vent valve is opened to allow for controlled release of gas. This step is crucial to prevent overpressure while preparing the beverage for testing.

Shaking the Bottle: The tester requires the sample bottle to be shaken manually for 40 seconds. This process ensures the release of any trapped CO2 in the beverage, allowing for accurate pressure measurement.

Measuring Pressure and Temperature: After the shaking process, the tester records the pressure inside the container. A high-precision pressure gauge with multiple unit conversions (Mpa, PSI, etc.) ensures accurate readings. Simultaneously, the liquid temperature is measured.

Calculating CO2 Volume: Once the pressure and temperature are recorded, the data is cross-referenced with a carbonation volume table to determine the CO2 volume. This process provides a comprehensive assessment of carbonation levels, ensuring consistency and compliance with industry standards.

V. Compliance with ASTM F1115

The ASTM F1115 standard is critical for carbonation testing. It defines the methods used for measuring the carbonation levels of beverages in sealed containers. Compliance with this standard ensures that the testing process is accurate, repeatable, and consistent across various beverage types. ASTM F1115 also mandates that instruments used in carbonation testing, such as the Carbonation Tester, provide precise readings that meet specific tolerances for CO2 measurement.

VI. Key Technical Features of the Carbonation Tester

Durable Piercing Mechanism: The quenching piercing head is designed for repeated use, ensuring reliable bottle piercing without leakage.

High-Precision Pressure Gauge: The pressure gauge allows for multiple unit conversions, including MPa, PSI, and bar, to meet user preferences and international testing requirements.

Anti-Leakage Design: The tester’s anti-leakage system ensures that the sample remains intact during testing, providing accurate pressure measurements without interference from external factors.

Vent Valve and Exhaust Pipe: The integrated vent valve and exhaust pipe allow for controlled gas release, minimizing the risk of overpressure or incorrect readings.

Manual Shaking Process: While many testers feature automatic shaking, the manual shaking feature allows for greater control over the testing process, making the Carbonation Tester highly versatile.

VII. Technical Specifications

| Test Range | 0~1MPa |

| Resolution | 0.0001MPa |

| Shaking | Manual |

| Piercing | Manual |

| Sample Height | ≤ 350mm (other available) |

VIII. Why Choose Cell Instruments’ Carbonation Tester?

When it comes to carbonation testing, accuracy and reliability are essential. Our Carbonation Tester is designed to meet the rigorous demands of beverage manufacturers while adhering to international standards like ASTM F1115. With high-precision pressure measurement, anti-leakage design, and customizable features, our tester offers a superior solution for CO2 volume testing.

Additionally, Cell Instruments is committed to providing customizable options for unique testing needs, as well as automation transformation services. Whether you’re testing soft drinks, beer, or pharmaceuticals, our carbonation testers provide the precision and reliability your products require.

FAQs

What is a Carbonation Tester used for?

A carbonation tester is used to measure the CO2 volume in carbonated beverages such as soft drinks, beer, and sparkling water. It ensures that products meet quality standards by accurately measuring carbonation levels.How does the Carbonation Tester ensure accuracy?

The tester uses a combination of pressure and temperature measurements, which are then cross-referenced with a carbonation volume table to determine the exact CO2 content. This ensures consistent and accurate results.What is ASTM F1115, and why is it important?

ASTM F1115 is a standard that outlines the methods for measuring carbonation in sealed containers. Compliance with this standard ensures that the testing process is accurate and consistent, providing reliable results.Can the Carbonation Tester be customized?

Yes, Cell Instruments offers customization options to meet specific testing requirements, including adjusting sample height and automation features.What industries benefit from using the Carbonation Tester?

The tester is widely used in the beverage industry (for soft drinks, beer, sparkling water), food packaging, pharmaceuticals, and quality control agencies.

Related Model

CLRT-01 Automatic Beverage Carbonation Tester