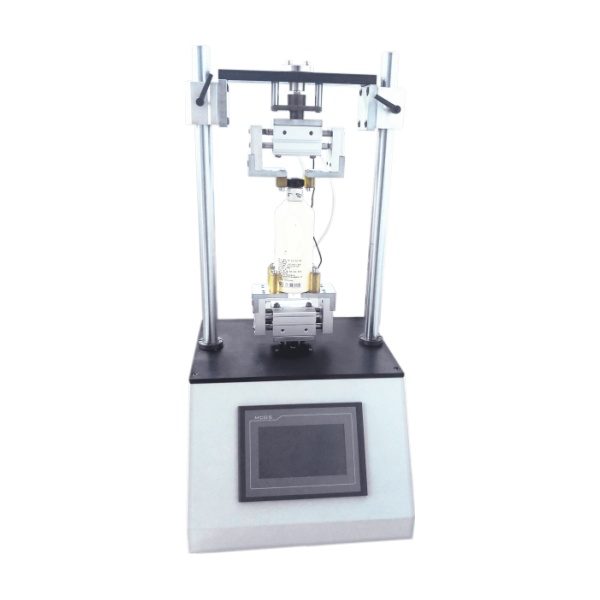

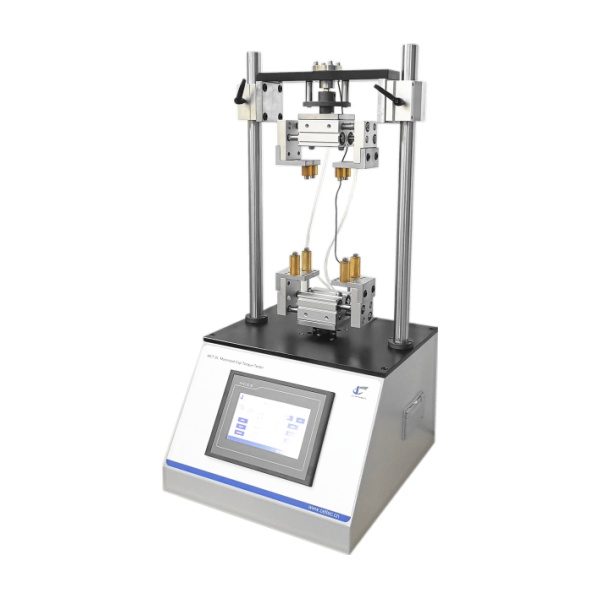

MCT-01 Motorized Cap Torque Tester

- Standard: ASTM D2063, ASTM D3198, ASTM D3474, GB/T17876, BB/T0025, BB/T0034

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

Cap torque testers are essential instruments designed to measure the torque required to open or close caps on bottles, jars, and other containers. These devices ensure that the caps are neither too tight nor too loose, maintaining the integrity of the product inside. The automatic cap torque tester is a crucial tool across various industries, including packaging, pharmaceuticals, beverages, cosmetics, and household chemicals, ensuring product quality and safety by complying with standards such as ASTM D2063, ASTM D3198, and ASTM D3474.

I. Introduction of Cap Torque Testers

Importance in Various Industries

In the packaging industry, maintaining the appropriate torque is vital to ensure that containers are sealed properly, preventing leakage and contamination. In the pharmaceutical and food industries, correct torque levels ensure the safety and efficacy of the products, protecting them from external factors. Beverages also rely on precise torque measurements to maintain carbonation and freshness.

Benefits of Using Cap Torque Testers

Using an automatic cap torque tester offers numerous benefits:

- Quality Assurance: Ensures products meet quality standards and prevent customer complaints.

- Safety: Prevents under-tightened caps that could lead to leaks or contamination and over-tightened caps that could be difficult to open.

- Compliance: Meets industry standards such as ASTM D2063, ASTM D3198, and ASTM D3474.

- Efficiency: Automates the testing process, saving time and reducing human error.

II. Features and Specifications

Key Features

- PLC Controlled Unit: Ensures industrial-level stability with an intuitive HMI touch screen interface.

- Auto Clamping and Rotating Capability: Simulates a production line environment, enhancing real-world applicability.

- Measurement of Locking and Opening Forces: Provides comprehensive data on cap performance.

- Automatic Peak Value Retention: Captures the highest torque value for accurate assessment.

- Upper and Lower Dual Pneumatic Clamping Mechanisms: Secures various cap sizes and types firmly during testing.

- Automatic Rotation Functionality: Streamlines the testing process, allowing for consistent results.

- Micro Printer: Facilitates effortless data recording for quality control documentation.

- Multiple Units of Measurement: Displays results in Kgf.cm, N.cm, daN.cm, Inch.lbs, and N.m for versatility.

- Overload Protection and Auto-Zeroing Function: Enhances safety and accuracy.

- RS232 Port and Professional Computer Software (Optional): Allows for advanced data analysis and integration with other systems.

Technical Specifications

| Test Range | 10 Nm (or as required) |

| Accuracy | 1% FS |

| Resolution | 0.001 Nm |

| Clamp Range | Φ5mm~φ80mm for cap Φ5mm~φ170mm for bottle |

| Power | AC 110~220V |

III. Test Methods

Overview of Cap Torque Testing Procedures

- Preparation of Samples: Ensure caps and containers are clean and undamaged.

- Setting Up the Cap Torque Tester: Adjust settings according to the specific test requirements.

- Performing the Test: Use the automatic clamping and rotating functions to test the cap.

- Interpreting Results: Analyze the torque measurements to determine if they meet the required standards.

Types of Tests

- Application Torque Test: Measures the force required to apply the cap.

- Removal Torque Test: Measures the force required to remove the cap.

- Application/Removal Torque Test Cycle: Tests the cap through multiple application and removal cycles to ensure durability.

IV. Relevant ASTM Standards

ASTM D2063: Standard Test Methods for Measurement of Torque Retention for Packages with Continuous Thread Closures

- Scope and Purpose: Defines the procedures for measuring the torque retention of continuous thread closures.

- Detailed Test Procedures: Includes steps for sample preparation, testing, and data interpretation.

- Interpretation of Results: Provides guidelines for assessing compliance with torque retention requirements.

ASTM D3198: Standard Test Method for Application and Removal Torque of Threaded or Lug-Style Closures

- Scope and Purpose: Specifies the methods for measuring the application and removal torque of threaded or lug-style closures.

- Detailed Test Procedures: Outlines the precise steps to ensure accurate torque measurement.

- Interpretation of Results: Helps determine if the torque values fall within acceptable ranges.

ASTM D3474: Standard Practice for Calibration and Use of Torque Meters Used in Packaging Applications

- Scope and Purpose: Offers guidelines for the calibration and proper use of torque meters in packaging applications.

- Calibration Procedures: Describes the steps for calibrating torque meters to maintain accuracy.

- Best Practices for Use: Provides recommendations for the optimal use and maintenance of torque meters.

V. Applications

Industries Using Cap Torque Testers

- Packaging: Ensures containers are sealed correctly to prevent leaks and contamination.

- Food and Beverages: Maintains product freshness and safety by ensuring proper cap torque.

- Pharmaceuticals: Ensures the integrity and safety of medicinal products.

- Cosmetics: Prevents product spillage and maintains quality.

- Chemical and Household Products: Ensures safety and usability by maintaining proper sealing.

Specific Use Cases

- Ensuring Child-Resistant Closures: Tests caps for compliance with child safety standards.

- Verifying Tamper-Evident Features: Ensures tamper-evident caps function correctly.

- Quality Control in Production Lines: Integrates testers into production lines for continuous quality monitoring.

VI. Customization

Customization Options

- Tailoring Torque Ranges: Adjusts the tester to suit specific application requirements.

- Tailoring Sample Size Ranges: Modifies the tester to handle various cap sizes.

- Software Integration: Allows for advanced data analysis and reporting.

VII. FAQ

A1: Cap torque testing ensures that caps are applied with the correct torque, preventing leakage and maintaining product integrity. It’s crucial for quality control and compliance with industry standards.

A2: An automatic cap torque tester provides higher precision and consistency, reduces human error, and can simulate production line conditions, making it more suitable for industrial applications.

A3: Industries such as packaging, pharmaceuticals, food and beverages, cosmetics, and household chemicals benefit significantly by ensuring product safety and compliance.

A4: These ASTM standards provide rigorous, standardized methods for torque testing, ensuring reliable and reproducible results that meet industry regulations.

A5: Yes, many automatic cap torque testers come with RS232 ports and optional professional computer software for advanced data analysis and reporting.