Wrap Film Puncture Test

——ASTM D5748 Protrusion Puncture စမ်းသပ်မှု

ထုပ်ပိုးခြင်းရုပ်ရှင်များကို ထုပ်ပိုးခြင်းနှင့် ထုတ်ကုန်များကို ကာကွယ်ရန်အတွက် အဓိကအားဖြင့် လုပ်ငန်းအမျိုးမျိုးတွင် ကျယ်ကျယ်ပြန့်ပြန့်အသုံးပြုကြသည်။ ၎င်းတို့၏စွမ်းဆောင်ရည်ကိုဆုံးဖြတ်ရန်မရှိမဖြစ်လိုအပ်သောစမ်းသပ်မှုတစ်ခုမှာ wrap film puncture test ဖြစ်သည်။ ဤစမ်းသပ်မှုသည် ပစ္စည်း၏ တာရှည်ခံမှုနှင့် ကာကွယ်မှုစွမ်းရည်များကို သေချာစေရန်အတွက် အရေးကြီးသော ထိုးဖေါက်မှုစွမ်းအားများကို ဖလင်၏ ခံနိုင်ရည်အား အကဲဖြတ်သည်။

Wrap Film Puncture Test ဆိုတာဘာလဲ။

ထုပ်ပိုးထားသော ဖလင်ထိုးဖောက်စမ်းသပ်မှုတစ်ခုသည် ရုပ်ရှင်တစ်ခု၏ ထိုးဖောက်ခြင်းအား ခံနိုင်ရည်အား တိုင်းတာသည် ။ ဤစမ်းသပ်မှုသည် ပြင်ပဖိအား၊ ချွန်ထက်သောအရာများ သို့မဟုတ် လွဲမှားစွာကိုင်တွယ်ခြင်းမှ ပါဝင်ပစ္စည်းများကို ကာကွယ်ရန် ရုပ်ရှင်များလိုအပ်သည့် ထုပ်ပိုးမှုလုပ်ငန်းများတွင် အထူးအရေးကြီးပါသည်။ ၎င်းသည် ရုပ်ရှင်များတွင် ရုပ်ပိုင်းဆိုင်ရာ ဖိစီးမှုများ ကြုံတွေ့နိုင်သည့် လက်တွေ့ကမ္ဘာအခြေအနေများကို တုပသည်။

စမ်းသပ်မှုတွင် ချွတ်ယွင်းချက်မဖြစ်ပေါ်မချင်း ထုပ်ပိုးထားသော ဖလင်နမူနာကို ထိုးနှက်မှုတွင် ပါဝင်ပါသည်။ ရလဒ်များသည် ထုတ်လုပ်သူများအနေဖြင့် ဖိစီးမှုအောက်တွင် ဖလင်သည် မည်မျှကောင်းစွာလုပ်ဆောင်ကြောင်းနှင့် ၎င်းသည် ပန်းကန်ပြားထုပ်ပိုးခြင်း၊ အစားအစာထုပ်ပိုးခြင်း သို့မဟုတ် ဆေးဘက်ဆိုင်ရာထုပ်ပိုးခြင်းကဲ့သို့သော သီးခြားအပလီကေးရှင်းများအတွက် သင့်လျော်မှုရှိမရှိကို ထုတ်လုပ်သူများအား နားလည်စေရန် ကူညီပေးပါသည်။

Puncture Resistance ကို ထိခိုက်စေသော အဓိကအချက်များ

ထုပ်ပိုးထားသော ရုပ်ရှင်များ၏ ထိုးနှက်ခံနိုင်ရည်အား လွှမ်းမိုးသည့် အချက်များစွာ အပါအဝင်၊

- ပစ္စည်းဖွဲ့စည်းမှု: အသုံးပြုထားသော ပိုလီမာ အမျိုးအစား (ဥပမာ- သိပ်သည်းဆနည်းသော polyethylene၊ သိပ်သည်းဆမြင့် polyethylene၊ သို့မဟုတ် polypropylene) သည် ရုပ်ရှင်၏ မာကျောမှုနှင့် ပြောင်းလွယ်ပြင်လွယ်အပေါ် သက်ရောက်မှုရှိသည်။

- ရုပ်ရှင်အထူ: ပိုထူသောရုပ်ရှင်များသည် ယေဘူယျအားဖြင့် ပိုမိုမြင့်မားသော ထိုးဖောက်မှုကို ခံနိုင်ရည်ရှိသော်လည်း ၎င်းတို့သည် ပြောင်းလွယ်ပြင်လွယ်ကို စွန့်စားနိုင်ပါသည်။

- Stretching Properties ၊: ပိုဆန့်သောရုပ်ရှင်များသည် တွန်းအားပိုကောင်းစေပြီး ထိုးဖောက်ခံရနိုင်ခြေကို လျော့ကျစေသည်။

- ပတ်ဝန်းကျင်အခြေအနေများ: အပူချိန်နှင့် စိုထိုင်းဆကဲ့သို့သော အကြောင်းရင်းများသည် ပစ္စည်း၏ ထိုးဖောက်ခြင်းခံနိုင်ရည်ကို ပြောင်းလဲစေနိုင်သည်။

ဤအချက်များအား နားလည်သဘောပေါက်ခြင်းသည် တိကျသော ကြံ့ခိုင်မှုလိုအပ်ချက်များနှင့် ကိုက်ညီသော ထုပ်ပိုးရုပ်ရှင်များထုတ်လုပ်ရန်အတွက် ထုတ်လုပ်သူများအတွက် မရှိမဖြစ်လိုအပ်ပါသည်။

Wrap Film Puncture Test ကို ဘယ်လိုဆောင်ရွက်ပါသလဲ။

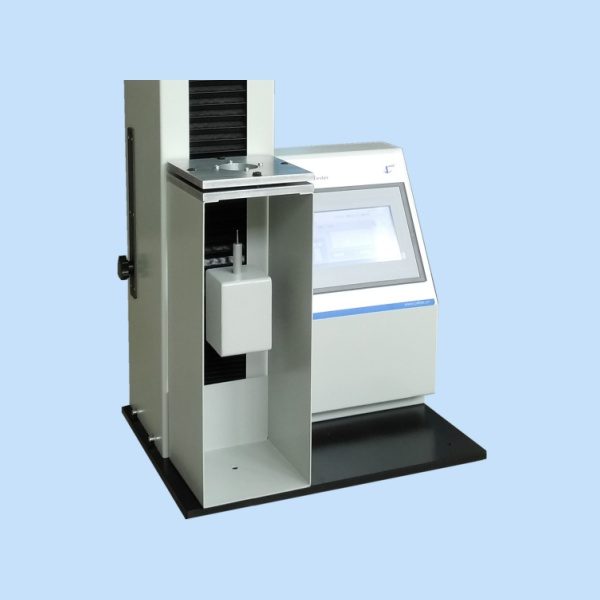

ထုပ်ပိုးထားသော ဖလင်ထိုးဖောက်စစ်ဆေးမှုကို ပုံမှန်အားဖြင့် ထိုးဖောက်မှုအခြေအနေများကို အတုယူရန် ဒီဇိုင်းထုတ်ထားသော အထူးပြုကိရိယာများကို အသုံးပြု၍ လုပ်ဆောင်သည်။ အသုံးအများဆုံး တပ်ဆင်မှုတွင် ပစ္စည်းပျက်သွားသည့်တိုင်အောင် ဖလင်နမူနာထဲသို့ တိုးလာသော အင်အားဖြင့် ဖိထားသည့် ထိုးဖောက်မှုတစ်ခု ပါဝင်ပါသည်။ ထိုးဖောက်ခြင်းဖြစ်ပေါ်သည့် တွန်းအားကို မှတ်တမ်းတင်ထားပြီး ထိုးဖောက်ခြင်းခံနိုင်ရည်တန်ဖိုးကို တွက်ချက်သည်။

ASTM D5748 သည် ရုပ်ရှင်များနှင့် အလားတူပစ္စည်းများအတွက် ထိုးဖောက်စမ်းသပ်မှုများ ပြုလုပ်ခြင်းဆိုင်ရာ လမ်းညွှန်ချက်များ ပေးပါသည်။ ၎င်းသည် စမ်းသပ်မှုလုပ်ထုံးလုပ်နည်း၊ စက်ကိရိယာလိုအပ်ချက်များနှင့် ရလဒ်များကို မည်သို့အနက်ဖွင့်ဆိုသည်ကို ဖော်ပြသည်။ ဤစံနှုန်းများကို လိုက်နာခြင်းသည် စမ်းသပ်မှုရလဒ်များတွင် လိုက်လျောညီထွေရှိပြီး ယုံကြည်စိတ်ချရမှုကို သေချာစေပြီး ဒေတာကို နှိုင်းယှဉ်ခွဲခြမ်းစိတ်ဖြာမှုအတွက် ပိုမိုအသုံးဝင်စေသည်။

Pallet Wrap Protrusion Puncture Resistance- ထုပ်ပိုးမှုတွင် အရေးပါမှု

pallet wrapping ၏အခြေအနေတွင်၊ protrusion puncture resistance သည် အရေးကြီးသောအခန်းကဏ္ဍမှ ပါဝင်ပါသည်။ ကုန်ပစ္စည်းများကို အလွှာတစ်ခုပေါ်တွင် ထုပ်ပိုးသည့်အခါ၊ ထုပ်ပိုးထားသော ဖလင်သည် ချွန်ထက်သောထောင့် သို့မဟုတ် အစွန်းများကဲ့သို့ အပေါက်များထွက်နေသော အရာဝတ္ထုများ၏ ဖိအားကို ခံနိုင်ရည်ရှိရပါမည်။

ချွန်ထက်သောအရာ (လက်သည်း သို့မဟုတ် သတ္တုအစွန်းများကဲ့သို့) ဖလင်ထဲသို့ ဖိလိုက်သောအခါ ထုပ်ပိုးထားသည့် ဖလင်တစ်ခုသည် အပေါက်ဒဏ်ကို မည်မျှကောင်းစွာ ခံနိုင်ရည်ရှိမည်ကို တိုင်းတာသည့် အပေါက်ဖောက်ခြင်း စမ်းသပ်မှု။ ဤစမ်းသပ်မှုသည် ထုတ်လုပ်သူအား သယ်ယူပို့ဆောင်ရေးနှင့် သိုလှောင်မှုအတွင်း ၎င်းတို့၏ ခိုင်မာမှုကို ထိန်းသိမ်းပေးမည့် ရုပ်ရှင်များကို ရွေးချယ်စေပြီး ထုပ်ပိုးထားသော ကုန်ပစ္စည်းများ ပျက်စီးမှုကို ကာကွယ်ပေးပါသည်။

ချွန်ထက်သော အရာဝတ္ထုများနှင့် ထုပ်ပိုးထားသော ထုတ်ကုန်များနှင့် ထိတွေ့နိုင်သည့် လက်တွေ့ဘဝအခြေအနေများကို ပုံတူကူးထားသည့် ပွန်းပေါက်ထိုးဖောက်စမ်းသပ်မှုအား အသုံးပြု၍ အချွန်အတက်များကို ခံနိုင်ရည်ရှိစေရန် စမ်းသပ်ခြင်းကို ပုံမှန်အားဖြင့် ထိန်းချုပ်ထားသော အခြေအနေအောက်တွင် လုပ်ဆောင်ပါသည်။

Wrap Film Puncture Test တွင် ASTM D5748 ၏ အခန်းကဏ္ဍ

ASTM D5748 စမ်းသပ်မှုရလဒ်များသည် ယုံကြည်စိတ်ချရပြီး မတူညီသောနမူနာများ သို့မဟုတ် ထုတ်လုပ်သူများကြားတွင် နှိုင်းယှဉ်နိုင်စေရန်အတွက် ရုပ်ရှင်များတွင် ထိုးဖေါက်ခံနိုင်ရည်ကို တိုင်းတာခြင်းအတွက် စံသတ်မှတ်ထားသော လုပ်ထုံးလုပ်နည်းများကို ပံ့ပိုးပေးပါသည်။ စံနှုန်းသည် လိုအပ်သော စက်ကိရိယာများ၊ စမ်းသပ်မှု စနစ်ထည့်သွင်းမှုနှင့် ဒေတာကို မည်သို့အနက်ပြန်ဆိုရမည်ကို သတ်မှတ်ပေးပါသည်။

ASTM D5748 ကို လိုက်နာခြင်းဖြင့် ကုမ္ပဏီများသည် ၎င်းတို့၏ ထုပ်ပိုးထားသော ရုပ်ရှင်များကို လုပ်ငန်းဆိုင်ရာ စံနှုန်းများနှင့် ကိုက်ညီကြောင်း သေချာစေပြီး အမျိုးမျိုးသော အသုံးချပရိုဂရမ်များတွင် လုံလောက်သော အကာအကွယ်များ ပေးဆောင်နိုင်မည်ဖြစ်သည်။ စံနှုန်းသည် စမ်းသပ်မှုတွင် လိုအပ်သော တိကျမှုနှင့် တိကျမှုတို့ကို ထိုးထွင်းသိမြင်နိုင်ပြီး စစ်ဆေးမှုရလဒ်များ၏ ယုံကြည်စိတ်ချရမှုကို ပိုမိုတိုးတက်စေသည်။

Wrap Film Puncture Test ပြုလုပ်ခြင်း၏ အကျိုးကျေးဇူးများ

wrap film puncture test ကိုလုပ်ဆောင်ခြင်းသည် ထုတ်လုပ်သူနှင့် အရည်အသွေးထိန်းချုပ်ရေးပညာရှင်များအတွက် အကျိုးကျေးဇူးများစွာ ပေးသည်-

- ပိုမိုကောင်းမွန်သောထုပ်ပိုးမှုကြာရှည်ခံခြင်း။: ရုပ်ရှင်သည် ပို့ဆောင်ခြင်းနှင့် ကိုင်တွယ်ရာတွင် ကြုံတွေ့ရမည့် ဖိအားများကို ခံနိုင်ရည်ရှိစေရန် သေချာစေပါသည်။

- ဖောက်သည်စိတ်ကျေနပ်မှု တိုးစေခြင်း။: ပိုမိုကောင်းမွန်သော ထိုးဖေါက်မှုခံနိုင်ရည်ရှိသော ရုပ်ရှင်များကို ရွေးချယ်ခြင်းဖြင့် ကုမ္ပဏီများသည် ထုတ်ကုန်ပျက်စီးမှုအန္တရာယ်ကို လျှော့ချနိုင်ပြီး ပြန်လာမှုနှင့် တိုင်ကြားမှုများကို နည်းပါးလာစေသည်။

- စက်မှု စံချိန်စံညွှန်းများနှင့် ကိုက်ညီခြင်း။: ASTM D5748 ကို လိုက်နာခြင်းသည် ရုပ်ရှင်သည် စည်းမျဉ်းစည်းကမ်းနှင့် ဖောက်သည်ယုံကြည်မှုအတွက် မရှိမဖြစ်လိုအပ်သော သက်ဆိုင်ရာ အရည်အသွေးစံနှုန်းများနှင့် ကိုက်ညီကြောင်း သေချာစေပါသည်။

ထုပ်ပိုးခြင်းအတွက် အဘယ်ကြောင့် Puncture Test သည် မရှိမဖြစ်လိုအပ်သနည်း။

Wrap film puncture test သည် ရုပ်ရှင်ကြာရှည်ခံမှုကို အကဲဖြတ်ပြီး လက်တွေ့ကမ္ဘာအခြေအနေများအောက်တွင် ကောင်းမွန်စွာလုပ်ဆောင်နိုင်စေရန်အတွက် အရေးကြီးသောအစိတ်အပိုင်းတစ်ခုဖြစ်သည်။ ထိုးဖောက်ခြင်းကို ခံနိုင်ရည်ရှိစေသော အကြောင်းရင်းများကို နားလည်ပြီး ASTM D5748 ကဲ့သို့ စံချိန်စံညွှန်းများကို လိုက်နာခြင်းဖြင့် ထုတ်လုပ်သူများသည် သယ်ယူပို့ဆောင်ရေးနှင့် သိုလှောင်မှုအတွင်း ထုတ်ကုန်များအတွက် အကောင်းဆုံးကာကွယ်မှုပေးသည့် ရုပ်ရှင်များကို ဖန်တီးနိုင်သည်။

အထူးသဖြင့် အစားအသောက်၊ ဆေးဘက်ဆိုင်ရာနှင့် ဆေးဝါးများကဲ့သို့သော လုံခြုံပြီး ယုံကြည်စိတ်ချရသော ထုပ်ပိုးမှုအပေါ် အားကိုးသည့် စက်မှုလုပ်ငန်းများတွင် ထုပ်ပိုးထားသော ရုပ်ရှင်များမှ အကောင်းဆုံးစွမ်းဆောင်ရည်ကို ရရှိရန်အတွက် ယေဘူယျအားဖြင့် ထိုးဖေါက်ခံနိုင်ရည်နှင့် အချွန်အတက်များကို ခံနိုင်ရည်ရှိစေရန် စမ်းသပ်ခြင်းသည် သော့ချက်ဖြစ်သည်။