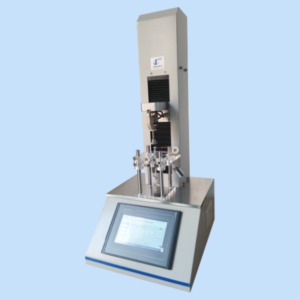

SLT-02 Syringe Leak Tester

- Πρότυπο: ISO 7886-1 Annex B, GB 15810

- Κατασκευαστής: Κυτταρικά όργανα

- Εφαρμογές: Υλικά συσκευασίας, υλικά ιατροτεχνολογικών προϊόντων, φαρμακευτικές δοκιμές και άλλα.

- Προσαρμογή: Διατίθεται για ειδικές απαιτήσεις δοκιμών και μετασχηματισμούς αυτοματισμού

Syringe leak testing is a crucial process in ensuring the quality and safety of hypodermic syringes used in various medical and pharmaceutical applications. The syringe leak testing machine plays an essential role in detecting air leakage past the plunger stopper and ensuring the integrity of the syringe’s seal.

What is Syringe Leak Testing?

Syringe leak testing is performed to verify that the syringe’s plunger stopper and seals do not allow air to leak past them under specific pressure conditions. This test ensures that syringes are free from leaks that could compromise their functionality, particularly for applications where precision and sterility are paramount, such as insulin injections or vaccines.

In the leak test, the syringe is partially filled with distilled water, and a vacuum is applied to test the integrity of the seals and the plunger stopper. If any air leaks past these components, it indicates that the syringe may not meet the required quality standards.

Syringe Leak Testing Machine System Overview

Ο SLT-02 Syringe Leak Tester is composed of a user-friendly control unit, a syringe stand, and a tube for securing the syringe during the test. The system operates by introducing compressed air into the control unit, which uses a venturi tube to generate a precise vacuum inside the syringe. The system’s design ensures stable vacuum holding throughout the testing process, delivering accurate and repeatable results.

Βασικά Χαρακτηριστικά

- Stable Vacuum Holding: The SLT-02 ensures consistent vacuum pressure throughout the test to accurately detect any air leakage or plunger stopper detachment.

- Efficient Vacuum Generation: The machine efficiently generates the necessary negative pressure, maintaining the required test conditions without interruption.

- Adjustable Fixture: The syringe fixture can be easily adjusted to accommodate syringes of various volumes, making the SLT-02 versatile for different syringe types and sizes.

- Λειτουργία φιλική προς το χρήστη: The SLT-02 is designed for ease of use, with a straightforward setup process and automatic operation after initiating the test.

- Durable Service Life: Built for long-term use, the SLT-02 is durable and reliable, ensuring continued performance over time with minimal maintenance.

Τεχνικό χαρακτηριστικό

| Εύρος δοκιμής | 0~-90KPa |

| Air Input | 0.6~0.7 Mpa |

| Test Time | 9999H |

| Εξουσία | 220V |

Configuration

- SLT-02 Leak Tester Control Unit

- Syringe Stand

- Tube for Syringe Connection

- Καλώδιο ρεύματος

- Ασφάλεια ηλεκτρική

Syringe Leak Testing Machine Test Principle

The testing process begins by connecting the syringe nozzle to a compatible connection tube. The syringe is then partially filled with water. A controlled negative pressure is applied via the nozzle, creating a vacuum inside the syringe. The system then monitors the syringe for any air leakage past the plunger stopper or seals. Additionally, it assesses whether the plunger stopper detaches from the plunger. This process simulates real-world conditions where syringes must remain sealed and functional under various pressures.

Benefits of Syringe Leak Testing Machines

Syringe leak testing machines offer several benefits, especially for manufacturers and quality control personnel:

- Ακρίβεια και Ακρίβεια: These machines provide highly accurate results, ensuring that syringes are free from leaks and meet ISO standards.

- Διασφάλιση Ποιότητας: By detecting even the smallest leaks, the machine helps ensure that syringes are safe for use in medical procedures.

- Συμμόρφωση: Syringe leak testing machines help manufacturers comply with ISO 7886-1 standards, which are crucial for obtaining certifications and ensuring the quality of their products.

- Αποδοτικότητα: Automated testing systems streamline the testing process, allowing for higher throughput and reduced human error.

ISO 7886-1 Testing Method for Air Leakage

ISO 7886-1 Annex B

ISO 7886-1 is an international standard that outlines the specifications for sterile hypodermic syringes, including guidelines for air leakage testing. Specifically, ISO 7886-1 Annex B provides a detailed test method for detecting air leakage past the syringe plunger stopper during aspiration, which is crucial for ensuring the syringe’s functionality.

Key elements of ISO 7886-1 testing include:

- Test Apparatus: The test setup includes a vacuum system, manometer, vacuum-tight valves, and a clamp to hold the syringe in place.

- Test Conditions: The syringe is subjected to a vacuum environment to simulate the conditions it would face during use. The test monitors the plunger’s ability to remain attached and whether any air leaks past the seals.

- Test Report: The results must be documented, including the syringe’s identity, the occurrence of leakage, any pressure changes, and whether the plunger stopper detached.

This standard ensures that syringes meet the necessary criteria for medical use, safeguarding both patients and healthcare professionals.

Διαδικασία δοκιμής

Ο air leakage test is a standard procedure used in syringe leak testing. According to ISO 7886-1, this method involves applying a vacuum to the syringe and measuring any change in pressure over time. Here’s a brief look at the typical steps involved:

- Filling the Syringe: The syringe is filled with distilled water, typically at least 25% of its nominal capacity.

- Applying the Vacuum: The syringe is connected to a vacuum system that generates a controlled negative pressure, typically reaching 88 kPa below ambient atmospheric pressure.

- Παρατήρηση για διαρροές: The syringe is then examined for any air leakage past the plunger stopper or seals. The manometer is monitored to check for any fall in pressure, indicating a leak.

- Testing for Plunger Detachment: The test also assesses whether the plunger stopper becomes detached from the plunger under vacuum conditions.

This method provides a reliable assessment of whether the syringe’s seals and plunger stopper are intact and functional.

Ο SLT-02 Syringe Leak Tester is an essential tool for syringe manufacturers and quality control teams who need to ensure that their syringes are leak-free and meet the required international standards, such as ISO 7886-1 Annex B. This reliable and efficient testing solution guarantees the integrity of syringes, making it an indispensable part of the quality assurance process in medical and pharmaceutical industries.