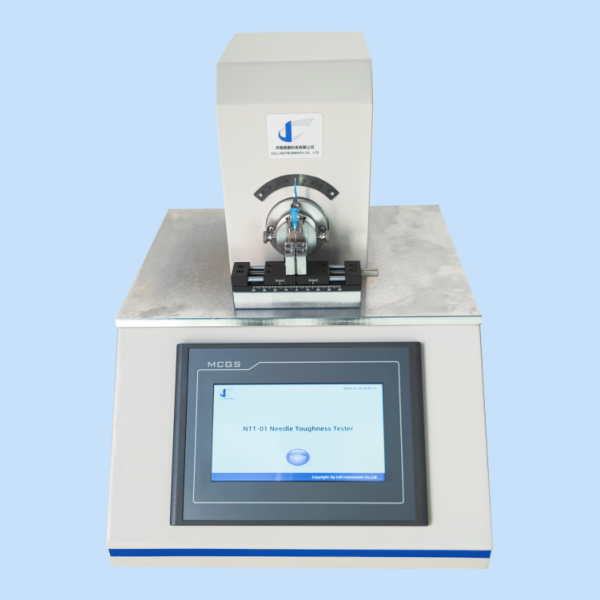

NTT-01 Needle Toughness Tester

Introduction to Needle Resistance to Breakage

Ensuring needle resistance to breakage is a critical part of medical device safety and reliability, particularly for hypodermic needles. Breakage during use can lead to serious injury, contamination, or product failure. The NTT-01 Needle Toughness Tester by Cell Instruments offers a precise, ISO 9626 solution for verifying the mechanical strength of stainless-steel needle tubing.

Why Needle Resistance to Breakage Testing Matters

In the realm of medical device manufacturing, especially for needles and catheters, mechanical failure during use poses significant risks. Needle resistance to breakage must be validated to ensure patient safety and product integrity. According to ISO 9626:2016, stainless steel needle tubing used in medical devices must undergo rigorous testing to confirm its durability under stress.

This standard, particularly Annex C, outlines a detailed method to evaluate the resistance of tubing to breakage. By following these requirements, manufacturers not only ensure compliance but also improve the market trustworthiness of their products.

Resistance of Tubing to Breakage – ISO 9626 Annex C Test Method

The bending test defined in ISO 9626 Annex C involves fixing one end of the tubing and applying a controlled force at a specific distance to bend the tubing in both directions through a defined angle. This test simulates the stresses the needle would encounter during actual clinical use.

- Bending Angles:

- (25 ±1)° for regular-walled tubing

- (20 ±1)° for thin-walled tubing

- (15 ±1)° for extra-thin and ultra-thin-walled tubing

- Test Cycles:

20 complete cycles of forward and reverse bending - Test Frequency:

0.5 Hz

After testing, the needle is visually inspected for signs of breakage. This procedure offers a standardized method to evaluate tubing toughness, aiding in quality assurance and regulatory compliance.

Introducing the NTT-01 Needle Toughness Tester

The NTT-01 Needle Toughness Tester is designed to perform the ISO 9626 Annex C test method with high precision and user-friendly controls. It enables manufacturers to assess the needle resistance to breakage across various tubing wall thicknesses with consistency and accuracy.

Working Mechanism

The device rigidly fixes one end of the tubing while applying force at a designated point to bend the tubing to the required angle. The system then reverses the direction and repeats the process, automatically managing test frequency and angle limits.

Key Features of the Needle Toughness Tester

This instrument is ideal for research labs, production lines, and quality control departments.

- PLC-Controlled with HMI Touchscreen: Enables intuitive operation and configuration.

- Two-Way and One-Way Bending Modes: Supports both test requirements.

- Adjustable Test Parameters: Including frequency, dwell time, and bending angle.

- Automatic Return Function: Ensures test integrity even in power failure situations.

- Integrated Microprinter: For immediate test result documentation.

Main Technical Parameters

| Parameter | Specification |

|---|---|

| Bending Mode | Two-way, one-way |

| Bending Angle | 15°, 20°, 25° |

| Test Frequency | 0.5 Hz |

| Napájení | 110~220V |

Standard Configuration

- Needle Toughness Tester

- Precision Caliper

- Napájecí kabel

- Pojistka

Applications in Medical and Related Industries

The NTT-01 is primarily used in testing hypodermic needles, catheters, and tubing in medical, pharmaceuticala syringe manufacturing sectors. It is also widely applicable to quality inspection agencies, ensuring end products comply with international safety standards like ISO 9626.

For companies looking to customize testing procedures or automate part of their quality assurance process, Cell Instruments offers tailored solutions designed to streamline operations without compromising accuracy.

Maintaining needle resistance to breakage isn’t just a regulatory necessity—it’s a matter of product integrity and user safety. With the NTT-01 Needle Toughness Tester, Cell Instruments delivers an advanced, compliant solution for manufacturers striving for excellence. Whether you’re testing standard medical tubing or custom-designed components, the NTT-01 ensures consistent performance and peace of mind.

To learn more about how the NTT-01 can improve your testing standards or to discuss automation transformation services, contact Buněčné nástroje Co., Ltd. today.