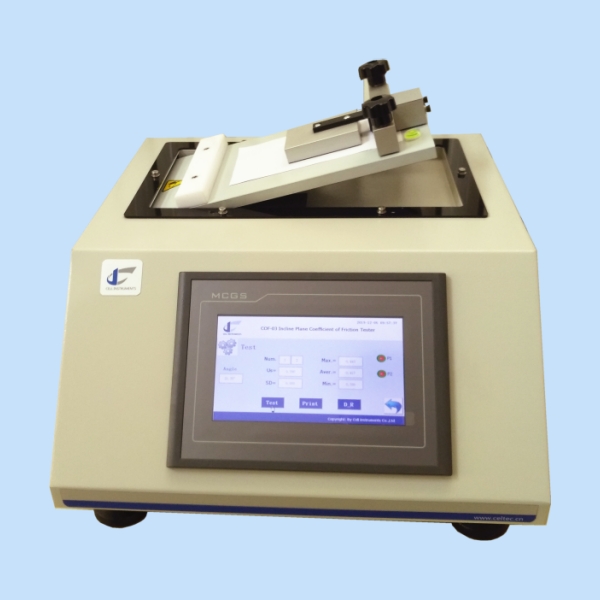

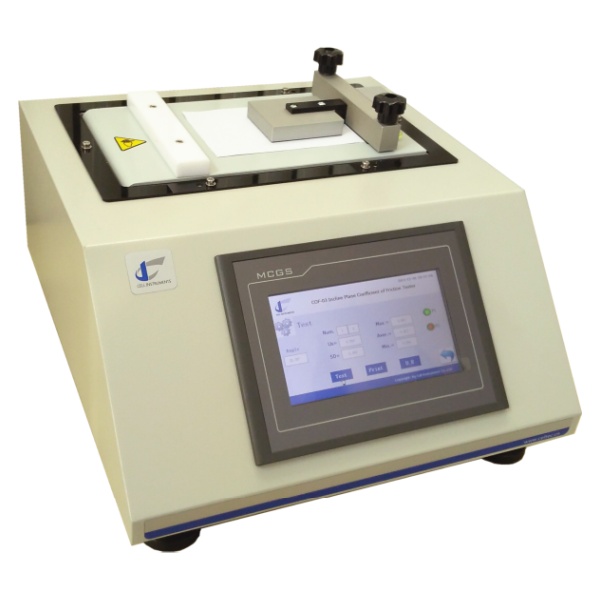

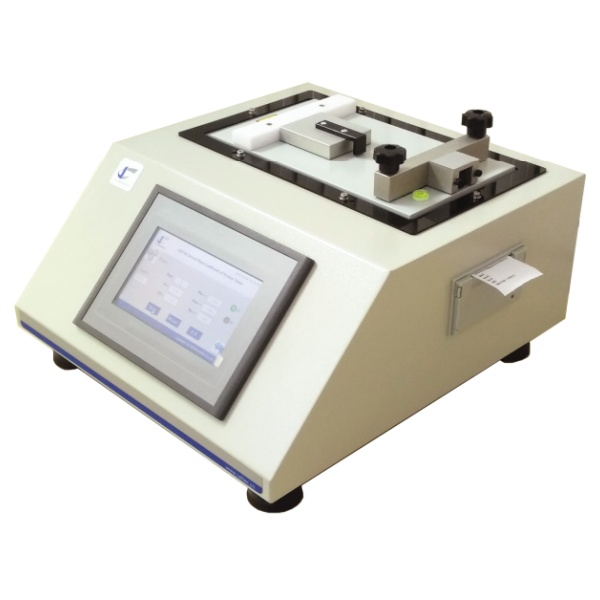

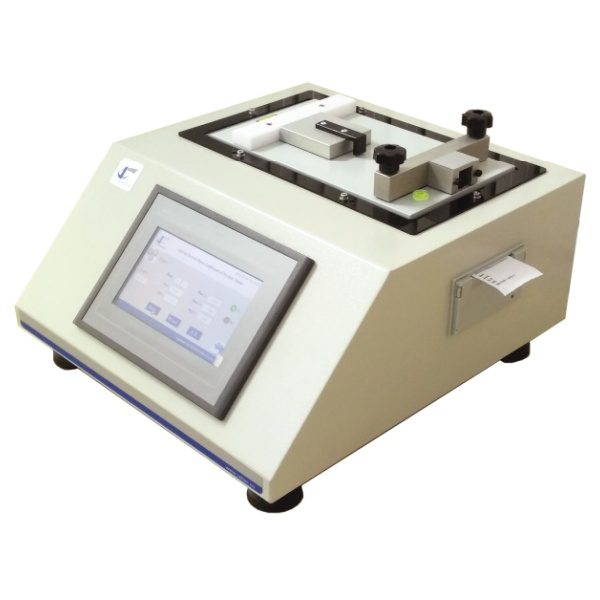

COF-03 Inclined Plane COF Testing Equipment

- Standard: ASTM D202, ASTM D4918, TAPPI T815

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

I. Introduction to Inclined Plane COF Testing Equipment

1. Brief Overview

The Coefficient of Friction (COF) is a critical parameter in material testing, representing the resistance to sliding motion between two surfaces. Understanding COF is essential in industries like packaging, medical devices, textiles, and pharmaceuticals, where material performance and safety are paramount. Inclined Plane COF Testing Equipment is designed to accurately measure this coefficient, providing valuable data for quality control and product development.

The importance of Inclined Plane COF Testing Equipment spans across various industries. In packaging, it ensures the stability and safety of packaged goods during transportation and handling. For medical devices, it helps evaluate the frictional properties of materials that come into contact with human skin or other surfaces. In textiles, it assesses the smoothness or roughness of fabrics, which can affect comfort and usability.

2. Key Features

Inclined Plane COF Testing Equipment boasts several advanced features, making it a reliable choice for material testing:

- PLC Control and HMI Touch Screen Operation: The equipment is equipped with a programmable logic controller (PLC) and a human-machine interface (HMI) touch screen for easy and precise operation.

- Real-Time Display of Test Results: It provides real-time display of maximum, minimum, average, and standard deviation of the test results, offering immediate insights into material properties.

- Compliance with Multiple International Standards: The equipment adheres to various international standards, ensuring its credibility and accuracy.

- Measurement of Both Angle and Static COF (Tangent Value): It can measure both the angle at which slippage occurs and the static COF, providing comprehensive data.

- Microprint Feature for Easy Printing of Test Results: A built-in microprint function allows for quick and convenient printing of test results.

- RS232 and Professional Software (Optional): The equipment offers RS232 connectivity and can be paired with professional software for enhanced data analysis and reporting.

II. Technical Specifications

The Inclined Plane COF Testing Equipment is designed to meet the highest standards of precision and reliability. Here are its key technical specifications:

| Angle range | 0° ~ 60° |

| Accuracy | 0.01° |

| Stroke | 0.1°/s ~ 10.0°/s |

| Sled | 200g, 235g, or 1300g(choose one or others) |

III. Test Methods Utilized by the Equipment

1. Overview of COF Testing

COF testing involves measuring the resistance to sliding motion between two surfaces. This parameter is crucial in determining the ease or difficulty with which materials slide over each other. In industries such as packaging, medical devices, textiles, and more, understanding COF helps in improving product performance, safety, and quality.

2. ASTM D202 Standard

The ASTM D202 standard outlines the procedures for determining the COF of materials. This standard is significant in ensuring consistent and reliable measurements.

- Scope and Significance: ASTM D202 covers the methods for testing the COF of materials used in various applications, ensuring uniformity and accuracy in measurements.

- Detailed Testing Procedure: The procedure involves placing a sample on the inclined plane, gradually increasing the angle until the sample starts to slide. The angle at which slippage occurs is recorded, and the COF is calculated.

- Interpretation of Results: The results from ASTM D202 provide insights into the material’s frictional properties, helping in quality control and product development.

3. ASTM D4918 Standard

The ASTM D4918 standard is another crucial guideline for COF testing, particularly focusing on the frictional properties of flexible packaging materials.

- Scope and Significance: ASTM D4918 addresses the methods for measuring the COF of flexible packaging materials, which is vital for ensuring the performance and safety of packaging products.

- Detailed Testing Procedure: Similar to ASTM D202, this procedure involves placing the sample on an inclined plane, adjusting the angle, and recording the slippage point. The static and kinetic COF values are calculated.

- Interpretation of Results: The results from ASTM D4918 help in assessing the slip resistance and handling characteristics of packaging materials, contributing to improved product performance.

IV. Applications of Inclined Plane COF Testing Equipment

Industry-Specific Uses

- Packaging: Ensuring stability and safety of packaged goods during transportation and storage.

- Medical Devices: Evaluating the frictional properties of materials used in medical devices to ensure patient safety and comfort.

- Pharmaceuticals: Testing the slip resistance of pharmaceutical packaging to prevent accidental opening and contamination.

- Adhesives: Measuring the adhesive quality and performance, ensuring reliability in various applications.

- Textiles: Assessing the frictional properties of fabrics, which affect comfort, wearability, and performance.

V. Benefits of Using Inclined Plane COF Testing Equipment

Enhanced Quality Control

Using Inclined Plane COF Testing Equipment enhances quality control by providing accurate and reliable COF measurements. This ensures that materials meet the required specifications and perform consistently.

Compliance with Standards

The equipment’s adherence to international standards like ASTM D202 and ASTM D4918 ensures that the testing methods and results are credible and universally accepted.

Cost Efficiency

By accurately measuring COF, manufacturers can reduce material waste and improve production efficiency, leading to significant cost savings.

Customization and Versatility

The equipment’s customizable testing parameters and versatile applications make it suitable for a wide range of testing needs across different industries.

VI. FAQ

A1: Measuring COF is crucial for understanding the frictional properties of materials, which affect product performance, safety, and quality in various industries.

A2: The equipment works by placing a sample on an inclined plane and gradually increasing the angle until the sample starts to slide. The angle at which slippage occurs is recorded, and the COF is calculated.

A3: The equipment complies with multiple international standards, including ASTM D202 and ASTM D4918, ensuring credible and accurate measurements.

A4: Yes, the equipment can measure both static and dynamic COF, providing comprehensive data on the material’s frictional properties.

A5: Industries such as packaging, medical devices, pharmaceuticals, adhesives, textiles, and more can benefit from using this equipment to ensure product performance and safety.