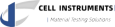

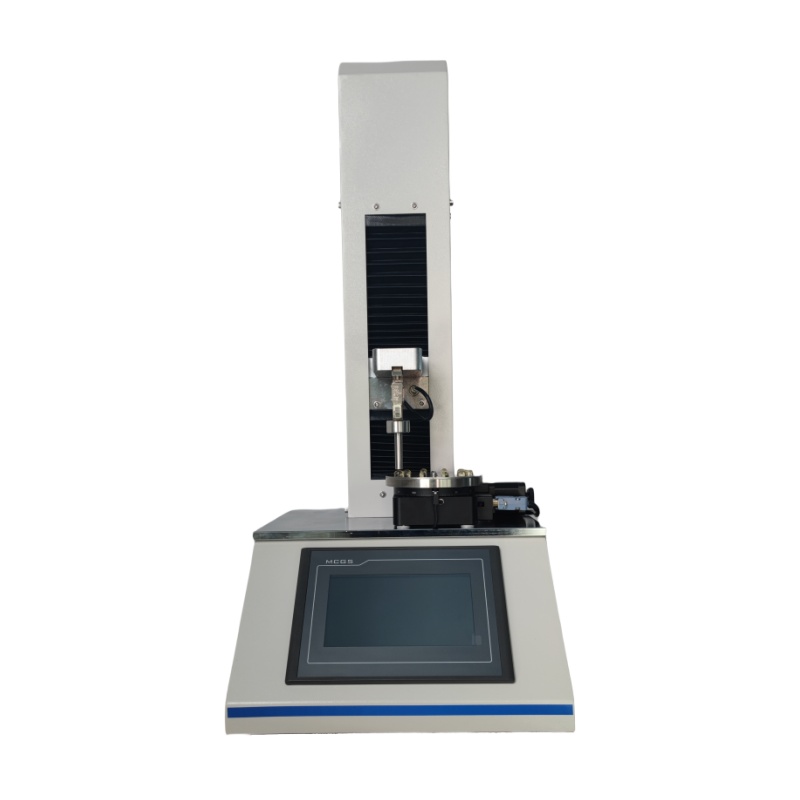

CHT-01 Gelatin Capsule Hardness Tester

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing,food testing, and more.

- Customization: Available for special testing requirements and automation transformations

I. Introduction to the Gelatin Capsule Hardness Tester

Ensuring the quality and consistency of gelatin capsules is paramount in the pharmaceutical industry. The Gelatin Capsule Hardness Tester, a specialized instrument from Cell Instruments, provides a reliable and precise method for testing the hardness of gelatin capsules. This state-of-the-art equipment is designed to meet the rigorous standards of pharmaceutical companies, quality control laboratories, research and development facilities, and packaging material testers. By utilizing advanced technology and user-friendly features, the Gelatin Capsule Hardness Tester guarantees accurate measurements, helping manufacturers maintain high product quality and regulatory compliance.

II. Key Features

1. Advanced Technology

The Gelatin Capsule Hardness Tester is equipped with a precision ball screw and stepper motor, ensuring high accuracy and repeatability in measurements. This advanced technology allows for precise control over the testing process, providing reliable data for assessing capsule hardness.

2. User-Friendly Operation

Designed with the user in mind, the tester features a PLC control unit and a 7-inch HMI touch screen, making it easy to operate. The interface is intuitive, allowing users to quickly set up and perform tests. The variable test speed feature accommodates different testing requirements, while multiple fixtures customization ensures versatility in testing various capsule sizes and shapes. Additionally, the position restrictor and overload protections enhance safety and prevent equipment damage. The automatic returning function after each test cycle and a dot matrix type microprinter for printing results further streamline the operation.

3. Standard Testing Items

The Gelatin Capsule Hardness Tester supports various standard testing items:

- Force: Set a force and record the distance until the force is reached.

- Peak: Obtain the maximum force in a rupture test.

- Distance: Measure the force at a certain distance.

III. Technical Specifications

| Test Range | 0~200N (Or as required) |

| Stroke | 200mm (without clamp) |

| Speed | 1~300mm/min(or as required) |

| Displacement Accuracy | 0.01mm |

| Accuracy | 0.5% F.S. |

| Output | Screen, Microprinter, RS232(optional) |

| Power | 110~ 220V 50/60Hz |

IV. Technical Features

1. Multi Test Programs

The tester’s multi-test programs allow for comprehensive analysis of capsule properties. These programs provide flexibility in testing and ensure thorough evaluation of capsule hardness.

2. Rotating Table

The rotating table feature increases test efficiency by allowing multiple capsules to be tested sequentially without manual intervention, saving time and effort.

3. Automatic Statics

Automatic statistical calculations help in quick analysis and data recording, enhancing productivity and accuracy.

4. Long and Durable Service Life

Constructed with high-quality materials, the tester ensures long and durable service life, making it a cost-effective investment for laboratories and manufacturers.

V. Applications

1. Pharmaceutical Industry

In the pharmaceutical industry, the Gelatin Capsule Hardness Tester is essential for ensuring the consistency and quality of gelatin capsules. It helps in maintaining compliance with regulatory standards, ensuring that products meet the required specifications.

2. Quality Control Laboratories

Routine testing in quality control laboratories is crucial for quality assurance. The tester provides reliable and repeatable results, ensuring that each batch of capsules meets the desired hardness criteria.

3. Research and Development

For research and development purposes, the tester aids in the development of new capsule formulations. It allows scientists to test various formulations and optimize their properties for better performance.

VI. Test Methods

1. Preparation of Samples

Proper preparation of gelatin capsules is crucial for accurate testing. The preparation involves cleaning the capsules and ensuring they are free from any external contaminants. Capsules should be conditioned at a controlled temperature and humidity before testing to ensure consistent results.

2. Testing Procedure

The detailed procedure for performing hardness tests includes:

- Calibration: Calibrate the tester to ensure accurate measurements.

- Sample Placement: Place the capsule in the testing fixture.

- Test Execution: Start the test by applying force or measuring distance as required.

- Data Recording: Record the results displayed on the screen.

Regular calibration and maintenance tips include checking the calibration standards and cleaning the fixtures after each use to maintain accuracy and longevity.

3. Data Interpretation

Interpreting test results involves understanding the force-distance relationship and peak force values. Typical results include maximum force readings indicating the capsule’s hardness. Examples of results might show variations in hardness due to different formulations or storage conditions.

VII. Customization and Services

Cell Instruments offers customization options to meet specific testing needs. Whether it’s adjusting the fixtures or modifying the software, our team can tailor the tester to suit unique requirements.

VIII. Benefits

1. Improved Product Quality

Using the Gelatin Capsule Hardness Tester ensures that capsules are consistently produced to the desired hardness, improving overall product quality.

2. Regulatory Compliance

The tester helps manufacturers adhere to industry standards and regulations, ensuring their products meet all necessary compliance requirements.

3. Cost Efficiency

Accurate and reliable testing reduces waste and improves production efficiency, leading to cost savings.

4. Enhanced Research Capabilities

Supporting innovative capsule formulations and testing methods, the tester is an invaluable tool for research and development teams.

IX. FAQ

Testing gelatin capsule hardness is crucial for ensuring product consistency, quality, and compliance with regulatory standards.

The tester’s rotating table feature allows for sequential testing of multiple capsules, saving time and effort.

Yes, the tester can be customized with multiple fixtures to accommodate various capsule sizes and shapes.