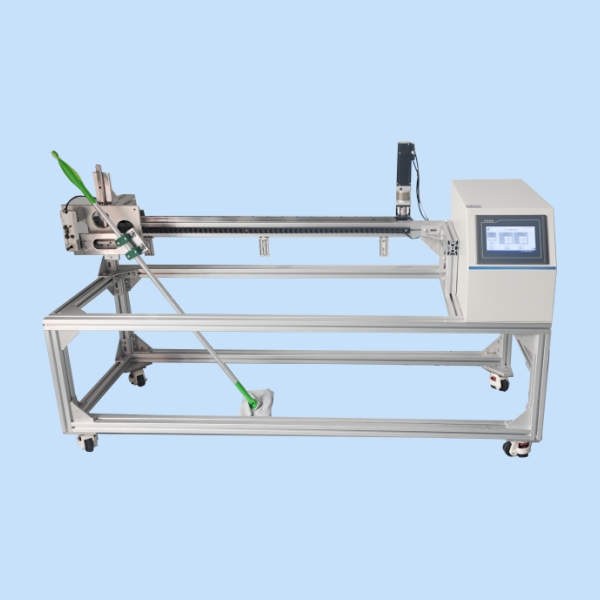

MopFric-01 Mop Friction Testing Machine

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

I. Introduction to the Mop Friction Testing Machine

The mop friction testing machine is an essential tool for evaluating the cleaning efficacy of various cleaning materials. At Cell Instruments, we specialize in producing high-quality materials testing instruments, including the advanced Mop Friction Testing Machine. This device is crucial for industries that require precise and reliable testing of cleaning materials, ensuring they meet the highest standards of performance.

II. Mop Friction Testing Machine Technical Feature

The Mop Friction Testing Machine from Cell Instruments combines flexibility and durability in its design. This advanced equipment is controlled by a PLC system and operated via a 7-inch Human-Machine Interface (HMI) touch screen, making it easy and intuitive to use. Its robust construction ensures industrial-level stability during operation. A high-speed linear guide ensures precision accuracy and high-speed performance.

Key features and specifications of the Mop Friction Testing machine include:

- 7-inch Human-Machine Interface: The touchscreen operation provides a simple and intuitive interface, offering a user-friendly experience.

- PLC Industrial Control System: This ensures stable and reliable testing processes, enhancing test precision.

- High-Precision Loadcell: With an accuracy of 0.5% FS, it provides real-time measurement of friction force data, ensuring accurate test results.

- Adjustable Testing Speed: The testing speed can be adjusted precisely from 1 to 60,000 mm/min as needed.

- Real-Time Data Display: Friction force data is displayed in real-time during the test, allowing users to monitor the process continuously.

- Easy Mobility: Equipped with casters, the tester can be easily moved to different testing locations.

III. Significance of Mop Friction Testing

Importance of Evaluating Cleaning Materials

Evaluating the friction and cleaning efficacy of mops and other cleaning materials is vital for ensuring their effectiveness in real-world applications. This testing helps manufacturers understand how their products perform under different conditions, leading to better product design and improved cleaning performance.

Benefits for Quality Assurance and Product Development

By using the Mop Friction Testing Machine, companies can ensure their products meet strict quality standards. This leads to enhanced customer satisfaction and trust. Additionally, the data obtained from these tests can drive innovation and product development, allowing manufacturers to create more effective cleaning solutions.

Impact on Production Efficiency and Product Quality

Accurate testing can identify potential issues early in the production process, reducing waste and improving efficiency. High-quality cleaning products not only perform better but also have a longer lifespan, providing better value to customers and reducing environmental impact.

IV. Test Methods

Step-by-Step Procedure for Using the Mop Friction Testing Machine

1. Securing the Sample: Attach the cleaning material sample to the aluminum or plastic frame of the Mop Friction Testing Machine. Ensure the sample is tightly secured to avoid any slippage during testing.

2. Positioning and Engagement: Place the secured sample vertically on the mobile arm of the tester. Ensure that the sample’s surface is fully engaged with the intended rubbing or sliding surface, such as tiles, wood, or glass.

3. Regulating Pressure and Movement: Manually adjust the applied pressure according to the test requirements. Set the movement speed and cycle count using the user-friendly interface. This step is crucial for simulating real-world cleaning scenarios.

4. Completing the Cycle Count: Run the machine for the designated number of cycles. The machine will simulate the cleaning action, allowing you to observe and record the performance of the cleaning material.

5. Additional Analysis and Parameters: After completing the cycles, perform additional analysis based on various parameters such as friction resistance, cleaning efficacy, and material wear. This data provides a comprehensive understanding of the material’s performance.

Explanation of Parameters and Outcomes Measured

Key parameters measured during the testing process include friction resistance, cleaning effectiveness, and durability of the cleaning material. These outcomes help manufacturers assess the overall quality and performance of their products.

Importance of Each Step in the Test Process

Each step in the test process is designed to simulate real-world conditions as accurately as possible. Securing the sample and positioning it correctly ensures that the test results are consistent and reliable. Regulating pressure and movement simulates different cleaning scenarios, providing valuable data on the material’s performance. Completing the cycle count and additional analysis offer a comprehensive evaluation of the cleaning material’s effectiveness and durability.

V. Applications

The Mop Friction Testing Machine is applicable in a wide range of industries, including:

Home Cleaning Products

Ensuring mops and cleaning cloths are effective in maintaining household cleanliness.

Office and Industrial Cleaning Materials

Testing industrial-grade cleaning materials for efficiency in large-scale cleaning operations.

Medical and Pharmaceutical Industries

Evaluating cleaning materials used in sterile and sensitive environments to ensure compliance with hygiene standards.

Packaging and Textiles

Assessing the cleaning performance of materials used in packaging and textile maintenance.

VI. Customization

At Cell Instruments, we understand that different industries have unique testing requirements. Therefore, we offer customization options for the Mop Friction Testing Machine, including:

- Software Customization: Tailoring the testing software to meet specific testing protocols and requirements.

- Program Customization: Developing custom testing programs to simulate unique cleaning scenarios.

- Fixture Customization: Designing and manufacturing custom fixtures to secure and test various cleaning materials.

VII. Benefits and Advantages

Enhanced Quality Control and Assurance

The tester ensures that cleaning materials meet stringent quality standards, leading to higher customer satisfaction.

Improved Production Processes

Identifying potential issues early in the production process reduces waste and increases efficiency.

Labor Savings and Efficiency

Automating the testing process saves labor and time, allowing for more tests to be conducted in less time.

Contribution to Product Development and Innovation

Accurate and detailed testing data drives innovation, enabling manufacturers to develop more effective cleaning solutions.

VIII. FAQ

1. What types of cleaning materials can be tested with the tester?

The tester is suitable for testing a variety of cleaning materials, including mops, cleaning cloths, and rags. It can simulate cleaning performance on surfaces such as tiles, wooden floors, and glass.

2. How does the tester ensure accurate and repeatable results?

The tester features adjustable pressure and speed controls, ensuring that each test is conducted under consistent conditions. This leads to accurate and repeatable results.

3. Can the tester be customized for specific testing requirements?

Yes, we offer customization options for software, programs, and fixtures to meet unique testing requirements across different industries.

4. What industries benefit most from using the tester?

The tester is beneficial for a wide range of industries, including home cleaning products, office and industrial cleaning materials, medical and pharmaceutical industries, and packaging and textiles.

5. What are the key parameters measured during the testing process?

The tester measures parameters such as friction resistance, cleaning effectiveness, and material wear, providing a comprehensive evaluation of the cleaning material’s performance.