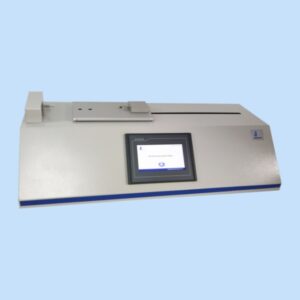

GLT-01 Gross Leak Bubble Tester

- Standard: ASTM F2096

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

I. Introduction to the Gross Leak Bubble Tester

A gross leak test for packaging is used to detect large, visible leaks in packaging by exposing the package to a pressure differential or vacuum, often using a tracer gas or dye to identify escaping air.

During the process, the package is placed in a test chamber where pressure or vacuum is applied. If there is a significant leak, the escaping gas or air will cause a detectable change in the chamber environment, making it possible to identify the leak.

This test is essential for ensuring that packaging integrity is maintained, particularly for sensitive products like pharmaceuticals and food, specific use cases include testing the integrity of packaging materials, medical device packaging, and pharmaceutical containers, and is commonly conducted in accordance with ASTM F2096 standards.

II. Technical Features

- High Sensitivity and Accuracy: The Gross Leak Bubble Tester provides reliable detection of even the smallest leaks by supplying gas in a stable manner.

- User-Friendly Interface: Equipped with an HMI touch screen, the tester offers an intuitive interface that simplifies the testing process.

- Customizable Testing Parameters: The PLC-controlled unit ensures industrial-level stability, allowing users to customize testing parameters to meet specific requirements.

- Durable Construction: Built to withstand rigorous testing environments, the tester’s robust construction ensures long-term use.

- Compliance with Industry Standards: Integration with the pressure decay test method is offered as an option, enhancing the tester’s versatility and compliance with various industry standards.

III. Technical Specifications

| Test Range | 0~30KPa (or as required) |

| Chamber Acrylic | 34*20*15cm LWH |

| Compressed Air | 0.6MPa (Prepared by user) |

| Power | 110~220V 50/60Hz |

IV. Gross Leak Detection – ASTM F2096 Bubble Test

ASTM F2096 is a widely recognized standard for gross leak detection in packaging materials. Gross leak testing involves submerging a test sample in water and applying a vacuum to detect leaks. This method is effective for identifying leaks that could compromise the integrity of packaging. astm bubble leak test samples can include various types of packaging materials, such as flexible pouches, rigid containers, and medical device packaging.

1. Step-by-Step Guide on Gross Leak Test

- Prepare the Tester: Turn on the tester and ensure all settings are configured correctly.

- Insert the Sample: Place the test sample in the designated chamber.

- Start the Test: Initiate the test by applying a vacuum.

- Monitor the Sample: Watch for bubbles emerging from the sample, indicating a leak.

- Record Results: Document the presence or absence of leaks for quality control records.

2. Interpretation of ASTM F2096 Bubble Test Result

According to ASTM F2096, Positive results (presence of bubbles) indicate a leak, requiring corrective action to ensure the packaging’s integrity. Negative results (no bubbles) confirm the sample’s integrity, ensuring it meets quality standards.

The Gross Leak Bubble Tester plays a vital role in quality control processes by providing accurate and reliable leak detection. This ensures that packaging materials maintain their integrity throughout their lifecycle, protecting the contents from contamination and damage.

FAQs

The tester can evaluate a variety of packaging materials, including flexible pouches, rigid containers, and medical device packaging.

The tester detects leaks by submerging the sample in water and applying a vacuum. The presence of bubbles indicates a leak.

Compliance with ASTM F2096 ensures that packaging materials meet necessary standards for leak integrity, preventing contamination and ensuring product safety.

Yes, we offer customization options to meet unique testing requirements, including tailored sizes, shapes, and testing conditions.

The tester plays a critical role in quality control by providing accurate and reliable leak detection, ensuring that packaging materials maintain their integrity and protect the contents effectively.

Reference

ASTM F2096 Standard Test Method for Detecting Gross Leaks in Packaging by Internal Pressurization (Bubble Test)