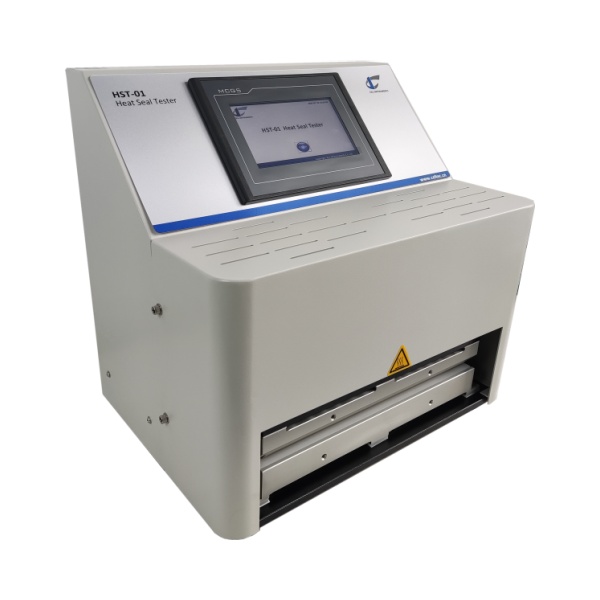

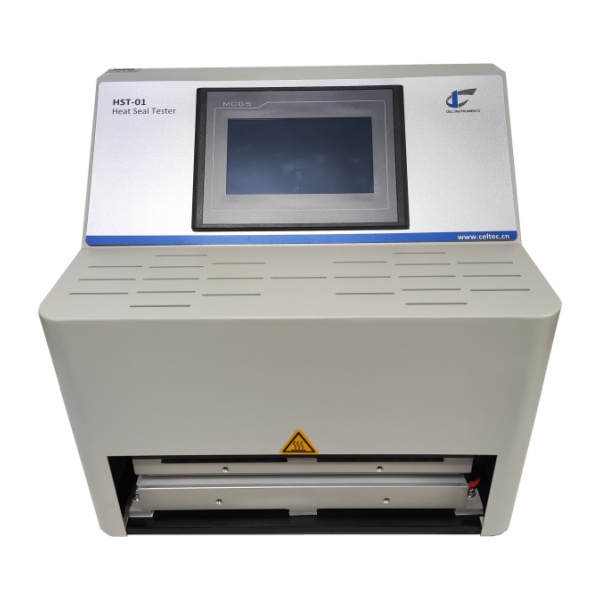

HST-01 Laboratory Heat Seal Tester

- Product Name: HST-01 Heat Seal Tester

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations.

I. Overview of the Heat Seal Tester

The Best Laboratory Heat Seal Tester, developed by Cell Instruments, is an advanced testing device designed for the precise evaluation of heat seals in various materials. This instrument is essential for industries such as packaging, medical devices, pharmaceuticals, textiles, and more. With a focus on compliance with ASTM F2029, the tester ensures that your materials meet stringent quality standards.

II. Features and Benefits

Precision

- The Best Laboratory Heat Seal Tester, developed by Cell Instruments, is an advanced testing device designed for the precise evaluation of heat seals in various materials. This instrument is essential for industries such as packaging, medical devices, pharmaceuticals, textiles, and more. With a focus on compliance with ASTM F2029, the Heat Seal Tester ensures that your materials meet stringent quality standards.

Versatility

- This tester is suitable for a broad range of materials, including plastics, textiles, paper, and adhesives. Whether you are testing the heat seal strength of food packaging or the integrity of sterile medical packaging, this device provides consistent and accurate results.

Customization

- Cell Instruments excels in tailoring solutions to meet specific testing requirements. The Heat Seal Tester can be customized to accommodate unique testing protocols or material specifications, providing a versatile tool that adapts to your needs.

Automation

- For enhanced efficiency and repeatability, the Heat Seal Tester offers automation options. Automated testing reduces human error and increases throughput, making it a valuable addition to any quality assurance process.

Compliance

- Fully compliant with ASTM F2029, the Heat Seal Tester ensures that your testing procedures meet industry standards. ASTM F2029 specifies the standard test method for making heat seals for determining the heat sealability of flexible webs as measured by seal strength. This compliance guarantees that your testing results are reliable and recognized globally.

III. Technical Specifications

| Sealing Temp. | Ambient~300℃ |

| Deviation | ±0.2℃ |

| Sealing Time | 0.1S~9999S |

| Sealing Pressure | 0.15~0.7 MPa |

| Seal Jaws | 330*10 mm L*W |

| Gas Pressure | 0.7 MPa |

| Port Size | Ф6 mm PU Hose |

| Power | AC 220V 50Hz |

IV. ASTM F2029 Standard

ASTM F2029 is the Standard Test Method for Making Heat Seals for Determination of Heatsealability of Flexible Webs as Measured by Seal Strength. This standard outlines the procedures for making and evaluating heat seals, ensuring consistency and reliability in testing.

Test Methods

Preparation of Test Specimens:

- Cut samples: Prepare samples of the material to specified dimensions, ensuring uniformity.

- Ensure cleanliness: Make sure the samples are free from defects and contaminants that could affect the seal quality.

Setting Test Parameters:

- Select parameters: Choose appropriate temperature, pressure, and dwell time settings based on the material.

- Record settings: Document the selected parameters for consistency and reproducibility.

Conducting the Test:

- Position sample: Place the sample between the heated sealing bars.

- Apply settings: Apply the pre-set pressure and hold for the designated dwell time.

- Cool sample: Remove the sample and allow it to cool before further analysis.

Measuring Seal Strength:

- Tensile testing: Use a tensile testing machine to pull the sealed sample apart.

- Record force: Measure and record the force required to break the seal, providing a quantitative measure of seal strength.

Test Contents

Seal Strength:

- The primary measure is the force required to separate the sealed materials. This quantifies the strength and reliability of the heat seal.

Seal Uniformity

- Assess the consistency of the seal across the sample, ensuring that the entire seal is uniform without weak spots.

Seal Appearance

- Evaluate the visual quality of the seal, looking for defects such as bubbles, wrinkles, or incomplete seals. A good seal should be smooth and uniform.

V. Applications

- Packaging Industry:Ensuring the integrity and quality of heat seals in flexible packaging materials, crucial for maintaining product freshness and safety.

- Medical Devices:Verifying the reliability of heat seals in sterile packaging, essential for preventing contamination and ensuring patient safety.

- Pharmaceuticals:Testing the seal strength of blister packs and other pharmaceutical packaging to ensure product integrity and compliance with regulatory standards.

- Adhesives:Evaluating the performance of adhesive heat seals in various applications, ensuring strong and durable bonds.

- Textiles:Testing heat-sealable fabrics used in technical textiles and garments, important for product durability and performance.

- Food and Beverages:Ensuring the safety and quality of sealed food and beverage packaging, vital for consumer protection and product shelf life.

- Quality Inspection Agencies:Providing standardized testing for compliance and quality assurance, ensuring products meet industry and regulatory standards.

FAQ

The tester is suitable for a wide range of materials, including plastics, textiles, paper, and adhesives. It is versatile enough to handle different thicknesses and compositions, making it ideal for various industry applications.

The tester is designed to fully comply with ASTM F2029 standards. It follows the prescribed test methods for making heat seals and measuring seal strength, ensuring that your testing procedures meet industry standards.

Yes, Cell Instruments specializes in customizing the tester to meet specific testing requirements. Whether you need unique parameter settings or specialized fixtures, the tester can be tailored to your needs.

Seal strength is measured using a tensile testing machine that pulls the sealed sample apart. The force required to break the seal is recorded, providing a quantitative measure of the seal’s strength and reliability.

Reference

ASTM F2029 Standard Practices for Making Laboratory Heat Seals for Determination of Heat Sealability of Flexible Barrier Materials as Measured by Seal Strength