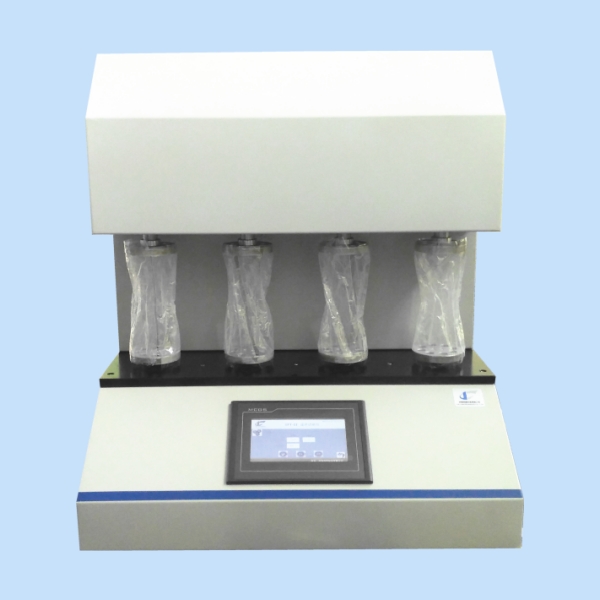

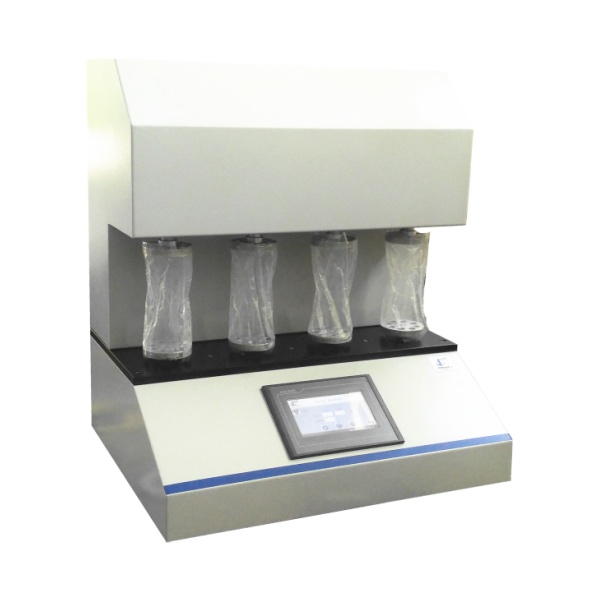

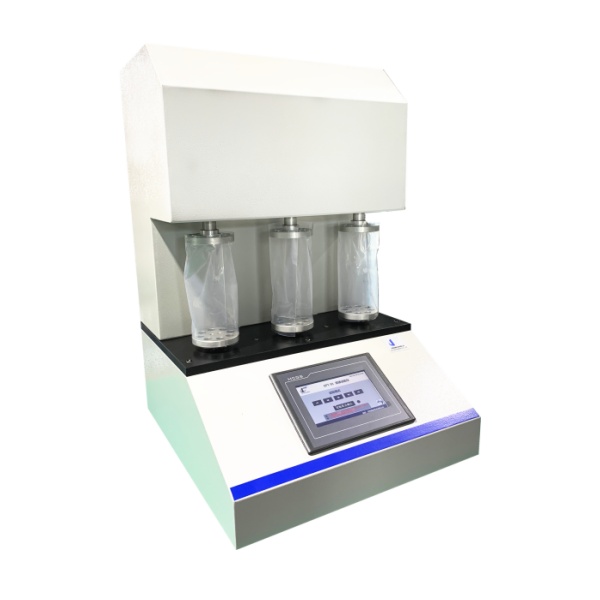

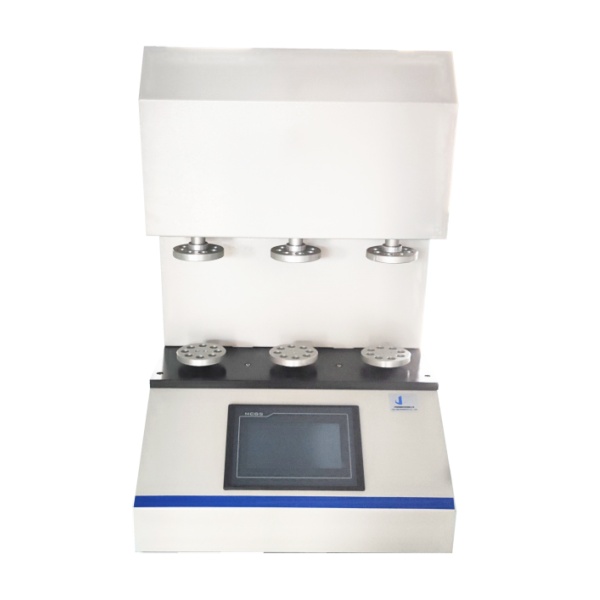

GFT Gelbo Flex Tester

- Standard: ASTM F392

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

I. Understanding the Gelbo Flex Tester

Definition of Flex Durability Tester

The tester is a specialized instrument designed to assess the flex durability of flexible barrier films. This testing is valuable in determining the resistance of flexible packaging materials to flex-formed pinhole failures.

Flex Durability Tester Operation Principle

Simulating real-world conditions, the tester repeatedly twists and flexes the sample to observing its resistance to flex.. This ensures that only the most durable packaging materials reach consumers.

II. Importance of Material Integrity in Flexible Packaging Industry and ASTM F392

ASTM F392 Standard Practice for Conditioning Flexible Barrier Materials for Flex Durability sets forth standardized procedures for evaluating the flex resistance of flexible barrier materials, ensuring adherence to rigorous quality standards and regulatory requirements.

III. Main Technical Parameters

| Flex Frequency | 45 /minute |

| Flex Angle | 440° (90 mm) or 400° (80 mm) |

| Capacity | 2.5 N.m |

| Horizontal Stroke | 155 mm or 80 mm |

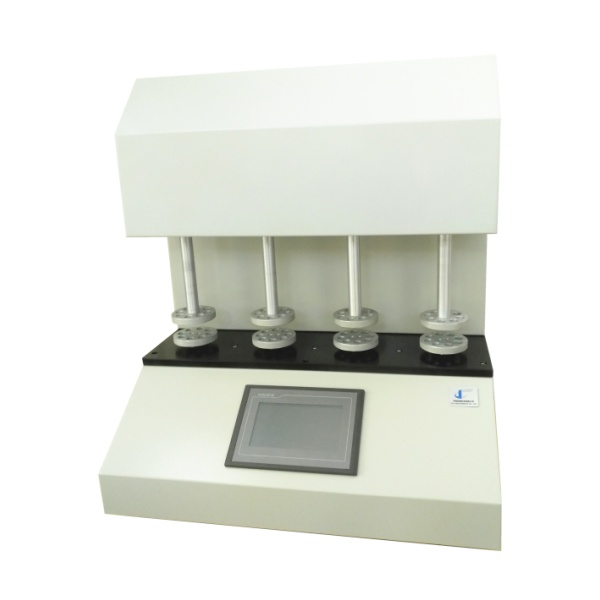

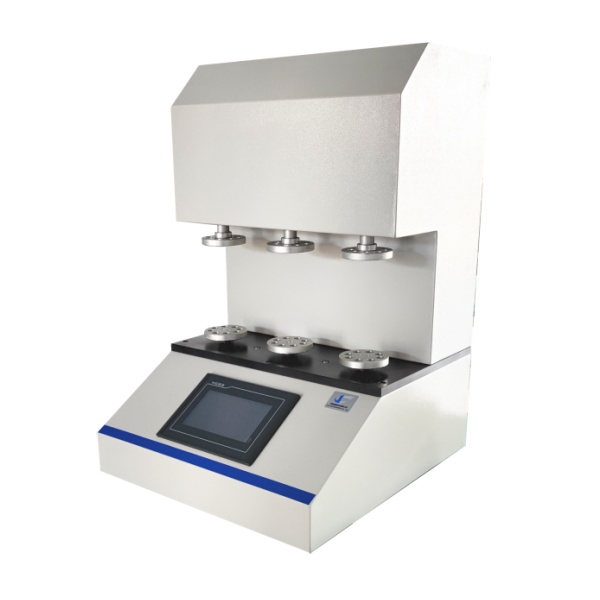

| Stations | 3/4 |

| Sample Size | 280 mm x 200 mm |

| Power | 110~220V |

IV. Unique Features of Cell Instruments’ Gelbo Flex Tester

The system features PLC control with an intuitive HMI touchscreen interface. It offers five standard test modes and includes four/three test stations. Users can quickly switch between long and short stroke modes. Test conditions A, B, C, D, and E are selectable, and the system is equipped with a micro printer for convenient data output.

V. Why Do We Need Gelbo Flex Tester

VI. Versatility Across Material Types

Material Compatibility

From flexible barrier films to textiles and beyond, the Gelbo Flex Tester exhibits remarkable versatility across a spectrum of materials. Its adaptable design accommodates diverse sample types, enabling comprehensive testing across various industries and applications.

Application Range

The applications of the Gelbo Flex Tester span far and wide, encompassing industries such as packaging, food, medical devices, pharmaceuticals, adhesives, and more.

VII. Meeting ASTM F392 with Cell Instruments’ Gelbo Flex Tester

The Tester does more than just meet the requirements set by ASTM F392; it offers a streamlined way to achieve compliance with detailed reporting that ensures not just repeatability but also unmatched accuracy.

VIII. FAQs

A: Cell Instruments’ Gelbo Flex Tester boasts a unique blend of precision engineering and innovative design features. From its intuitive user interface to its advanced automation capabilities, every aspect is meticulously crafted to optimize performance and user experience. Additionally, its compatibility across a wide range of materials and industries sets it apart as a versatile solution for flex testing needs.

A: By subjecting materials to rigorous flex testing, the flex durability tester helps identify weaknesses and potential failure points early in the development process. This proactive approach enables manufacturers to address issues before they escalate, resulting in products that are more resilient, reliable, and ultimately, of higher quality.

A: Absolutely! The Gelbo Flex Tester is designed to accommodate a wide range of sample sizes and shapes, offering flexibility and versatility in testing. Whether you’re working with small, delicate films or larger, bulkier materials, our tester can adapt to meet your specific testing requirements with ease.

A: Precision is paramount with the flex durability tester. Through meticulous calibration and robust construction, we ensure that each test yields consistent, dependable results. Additionally, our tester is designed to minimize external factors that could influence test outcomes, further enhancing accuracy and repeatability.

A: At Cell Instruments, we prioritize customer satisfaction and support. Our dedicated technical support team is available to assist users with any questions, concerns, or technical challenges they may encounter. Whether you need assistance with setup, calibration, or troubleshooting, our experts are here to provide prompt and effective support to ensure your testing processes run smoothly

Reference

ASTM F392 Standard Practice for Conditioning Flexible Barrier Materials for Flex Durability