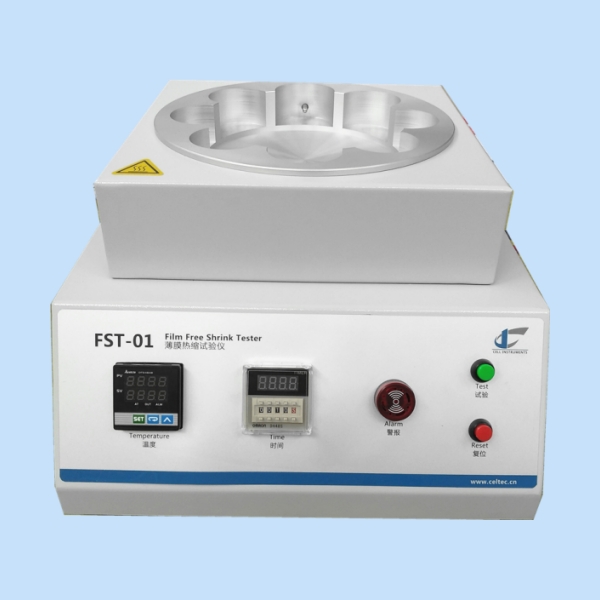

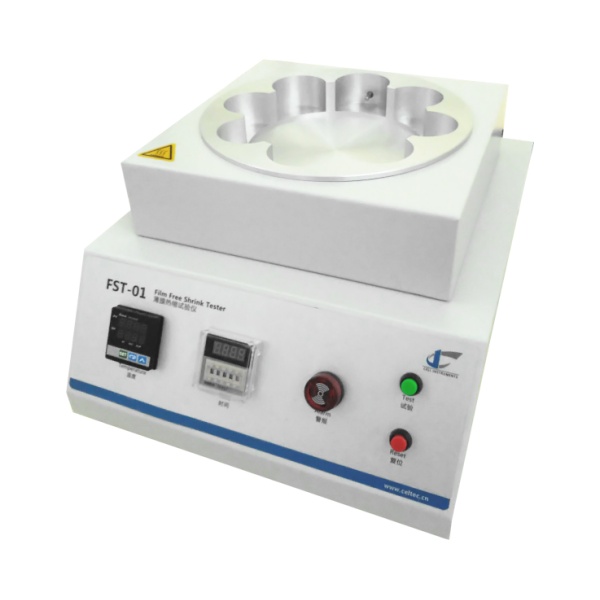

FST-01 Film Shrinkage Tester

- Standard: ASTM D2732

- Manufacturer: Cell Instruments

- Applications: Packaging materials, medical device materials, pharmaceutical testing, adhesives, textiles, paper and cardboard containers, and more.

- Customization: Available for special testing requirements and automation transformations

I. Introduction to Film Shrinkage Tester

Film Shrinkage Tester, a device specifically engineered to assess the thermal shrinkage of plastic films—an essential factor in maintaining the integrity and quality of packaging materials. Film shrinkage testing is a critical procedure in various industries, ensuring the quality and performance of plastic films used in packaging, medical devices, textiles, and more. At Cell Instruments, we specialize in providing advanced film shrinkage testers designed to meet the stringent requirements of ASTM D2732 standards.

II. Compliance with ASTM D2732 Standards

ASTM D2732 Standard Test Method for Unrestrained Linear Thermal Shrinkage of Plastic Film and Sheeting

The Film Shrinkage Tester is fully compliant with ASTM D2732 standards, ensuring that each test accurately reflects the shrinkage properties of plastic films under heat. This standard is pivotal for industries relying on consistent quality and performance of plastic materials, providing a benchmark for thermal shrinkage testing.

II. Technical Specifications and Features

- Precise P.I.D. Temperature Control: Experience unparalleled temperature control with our Precision Proportional-Integral-Derivative (P.I.D.) system, ensuring consistent and accurate results.

- High-Precision Timer: Seamlessly monitor testing durations with our high-precision timer, guaranteeing meticulous time management.

- Alarm Capability: Stay informed and alerted throughout the testing process with our intuitive alarm system, enhancing efficiency and reliability.

- Consistent Fluid Medium Heating: Achieve uniform heating of the fluid medium, essential for precise testing conditions and reliable outcomes.

- Inclusion of Standard Square Metal Clamp and Free Shrink Holder: Facilitating versatility and convenience, our tester comes equipped with essential accessories for varied testing requirements.

- Equipped with an Oil Bath Cover: Enhance safety and efficiency with our oil bath cover, ensuring optimal testing conditions while mitigating potential hazards.

IV. Testing Process

The testing process is streamlined and efficient, consisting of:

- Temperature Setup and Stabilization for accurate heat application.

- Specimen Preparation and Submersion in the precisely heated medium.

- Time Monitoring and Completion with the help of the integrated alarm system.

- Test Conclusion where the sample is carefully retrieved.

- Shrinkage Measurement and Assessment to determine the material’s performance.

V. Customization and Automation

Our film shrinkage testers can be customized to meet specific testing requirements and integrated with automation systems for enhanced efficiency and productivity. Whether you need specialized fixtures, software integration, or automated data collection, our team can tailor solutions to suit your needs.

VI. Application and Versatility

This tester is versatile, catering to industries such as packaging, pharmaceuticals, medical devices, and any sector where plastic film’s thermal properties are critical. Its capability to customize testing parameters makes it a valuable device for research and development, as well as production control.

VI. Why Choose Cell Instruments’ Film Shrinkage Tester

- Exceptional Quality: Our testers are manufactured using high-quality materials and cutting-edge technology, ensuring durability and long-term performance.

- Accurate Results: With adherence to ASTM standards and precision engineering, our testers deliver accurate and reproducible shrinkage measurements.

- Expert Support: Our team of technical experts provides comprehensive support, from design and calibration to ongoing maintenance and troubleshooting.

- Customization Options: We offer flexible customization options to meet the unique needs of your testing applications, ensuring maximum flexibility and efficiency.

VII. FAQ

A: Our film shrinkage tester employs precise P.I.D. temperature control technology, ensuring uniform heating of the fluid medium as per ASTM D2732 standards. Additionally, the high-precision timer allows users to monitor the test duration accurately, facilitating consistent results across multiple tests.

A: Yes, our tester is designed to accommodate a wide range of plastic film specimens, including different types and sizes. With standard square metal clamps and free shrink holders included, users can easily secure specimens of varying dimensions for comprehensive testing.

A: The duration of the shrinkage test depends on factors such as the type of plastic film and the testing conditions specified in ASTM D2732. However, with our high-precision timer and efficient heating system, most tests can be completed within a reasonable timeframe, typically ranging from a few minutes to an hour.

A: Absolutely. We offer customization options to tailor the equipment to your specific testing needs. Whether you require specialized fixtures, additional software features, or integration with automation systems, our team can work with you to develop a solution that meets your requirements and enhances efficiency.

Reference

ASTM D2732 Standard Test Method for Unrestrained Linear Thermal Shrinkage of Plastic Film and Sheeting